Eparam

Video manual on eparam usage is available below:

If an M-code (macro) is running from a G-code program, 16-bit integer parameters P and L are sent to the PLC procedure in the eparam variable.

P-parameter is in a low word of the eparam value and L-parameter is in high word of eparam value. To decode P and L parameters from eparam 2 simple lines of code can be used in the necessary PLC procedure:

P=eparam&0xFFFF;//P-parameter L=eparam>>16; //L-parameter

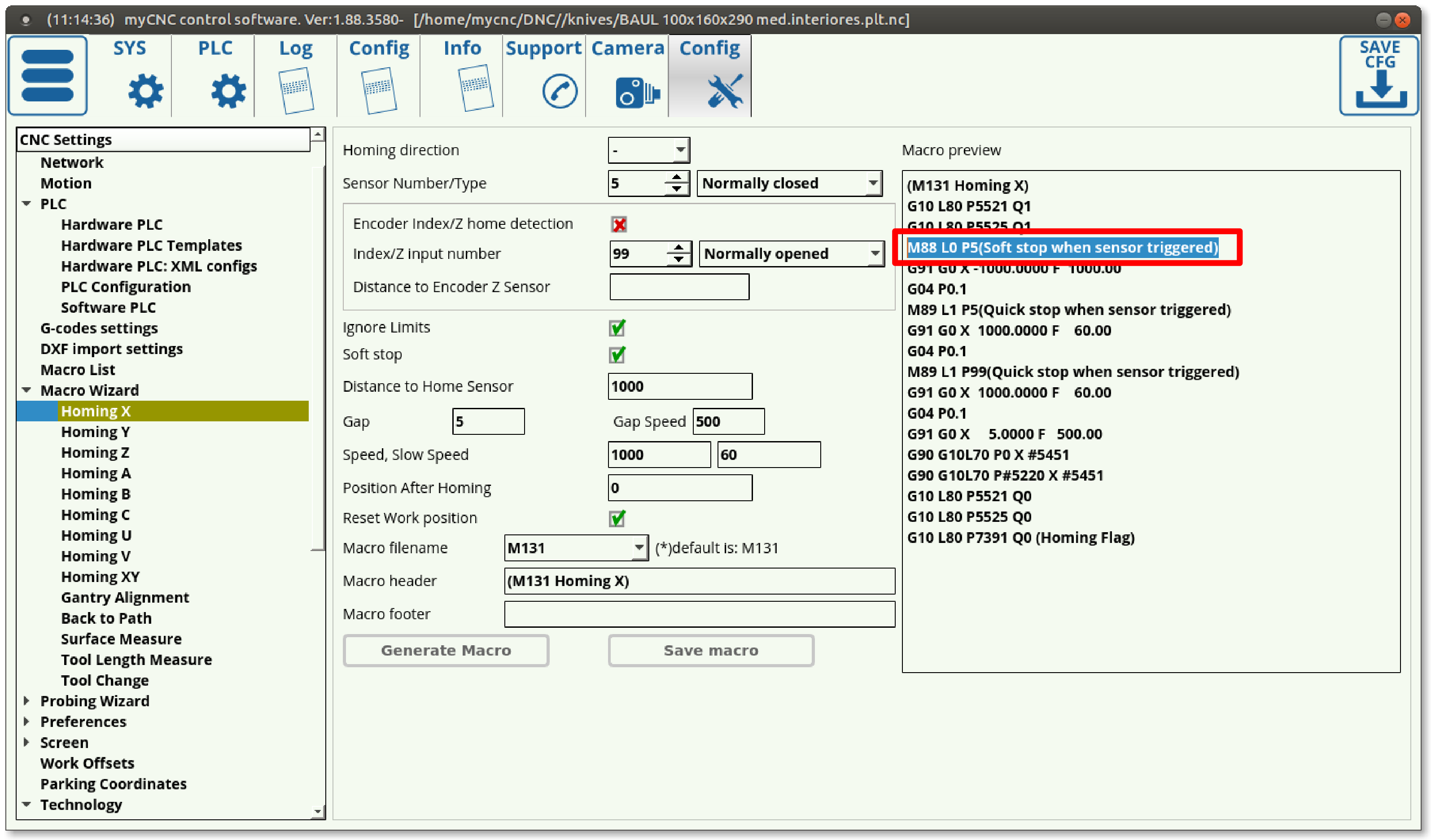

Eparam is often used in situations where it is necessary to send some value from the G-code or macro to a hardware PLC command which will use and incorporate this value. A good example of such a macro is the G-code for the X-axis homing procedure, since it relies on calling on a couple of Hardware PLC commands in order to perform the homing procedure:

- Homing X

(M131 Homing X) G10 L80 P5521 Q1 G10 L80 P5525 Q1 M88 L0 P5(Soft stop when sensor triggered) G91 G0 X -1000.0000 F 1000.00 G04 P0.1 M89 L1 P5(Quick stop when sensor triggered) G91 G0 X 1000.0000 F 60.00 G04 P0.1 M89 L1 P99(Quick stop when sensor triggered) G91 G0 X 1000.0000 F 60.00 G04 P0.1 G91 G0 X 5.0000 F 500.00 G90 G10L70 P0 X #5451 G90 G10L70 P#5220 X #5451 G10 L80 P5521 Q0 G10 L80 P5525 Q0 G10 L80 P7391 Q0 (Homing Flag)

Line 4 is using the L and P parameters to send an eparam value to the M88 macro.

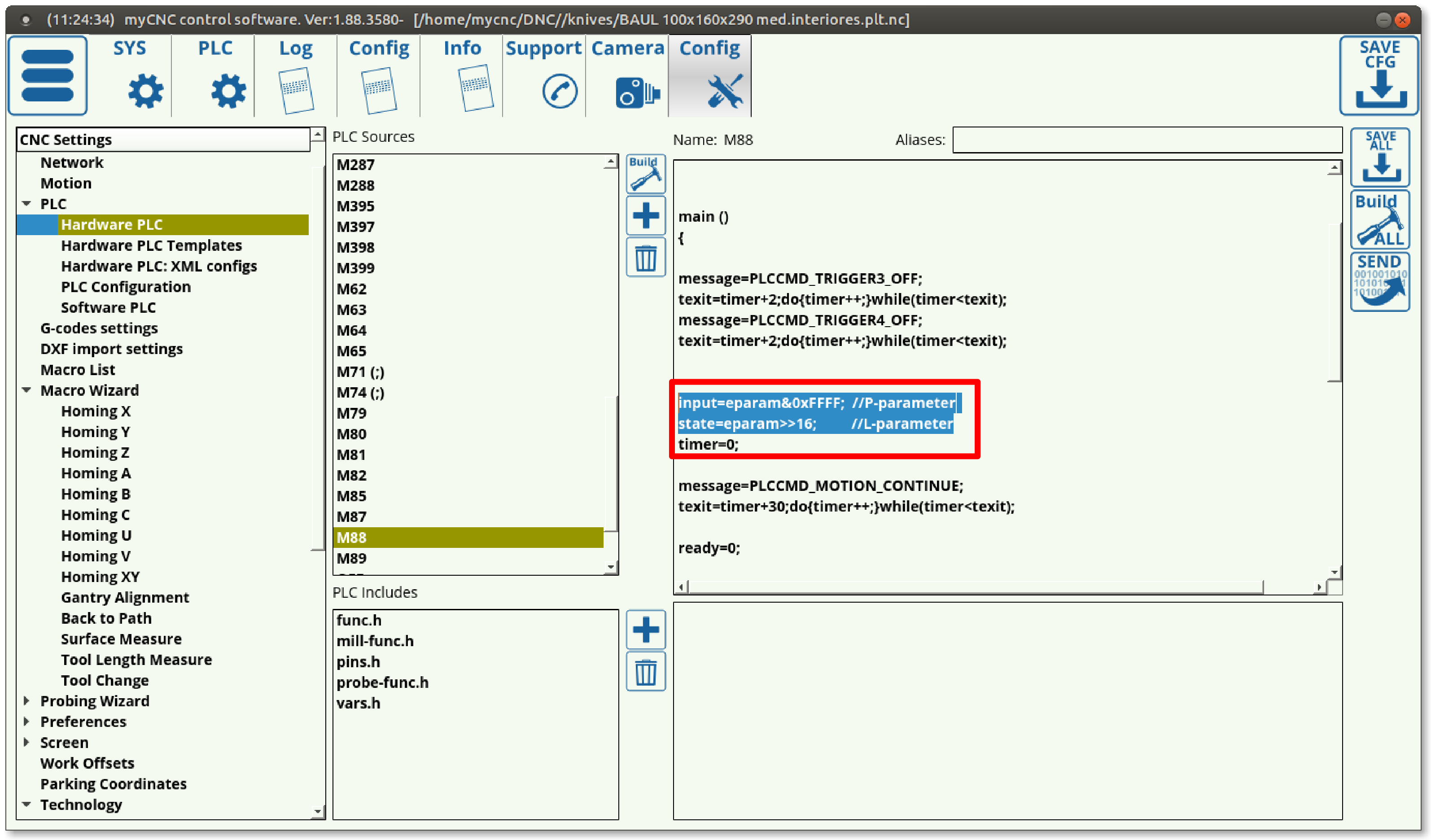

Below is the code for the M88 macro itself:

- M88.plc

#include common.const.h //Watch on given sensor number, Soft Stop if sensor triggered //used for homing, surface measure, tool length measure etc #define input var00 #define state var01 main () { message=PLCCMD_TRIGGER3_OFF; texit=timer+2;do{timer++;}while(timer<texit); message=PLCCMD_TRIGGER4_OFF; texit=timer+2;do{timer++;}while(timer<texit); input=eparam&0xFFFF; //P-parameter state=eparam>>16; //L-parameter timer=0; message=PLCCMD_MOTION_CONTINUE; texit=timer+30;do{timer++;}while(timer<texit); ready=0; do { timer++; a=portget(input); if (state==0) { if (a==0) {ready=1;}; }; if (state!=0) { if (a!=0) {ready=1;}; }; }while(ready==0); //message=PLCCMD_MOTION_SKIP; message=PLCCMD_MOTION_SOFT_SKIP; texit=timer+2;do{timer++;}while(timer<texit); exit(99); };

In this M88 code, you can see the eparam variable being “imported” into the macro that has been summoned by the G-code command. In this particular case, this allows to set the state and the necessary input number to monitor in order to initiate a soft stop when a particular sensor is triggered.

M03

A unique case of using the eparam value can be seen in the M03/SPN macros (spindle control). The M03 macro code is presented below:

- M03

//Turn on Spindle clockwise #include pins.h #include vars.h main() { timer=0; proc=plc_proc_spindle; val=eparam; if (val>0xfff) {val=0xfff;}; if (val<0) {val=0;}; dac01=val; portclr(OUTPUT_CCW_SPINDLE); portset(OUTPUT_SPINDLE); gvarset(7370,1);//Spindle State timer=30;do{timer--;}while (timer>0); // gvarset(7371,eparam);//Spindle Speed Mirror register timer=30;do{timer--;}while (timer>0); // //gvarset(7372,0);//Mist State //timer=30;do{timer--;}while (timer>0); // //gvarset(7373,0);//Flood State //timer=30;do{timer--;}while (timer>0); // //delay after spindle started timer=spindle_on_delay; do{timer--;}while (timer>0); //delay for Spindle reach given speed exit(99); //normal exit };

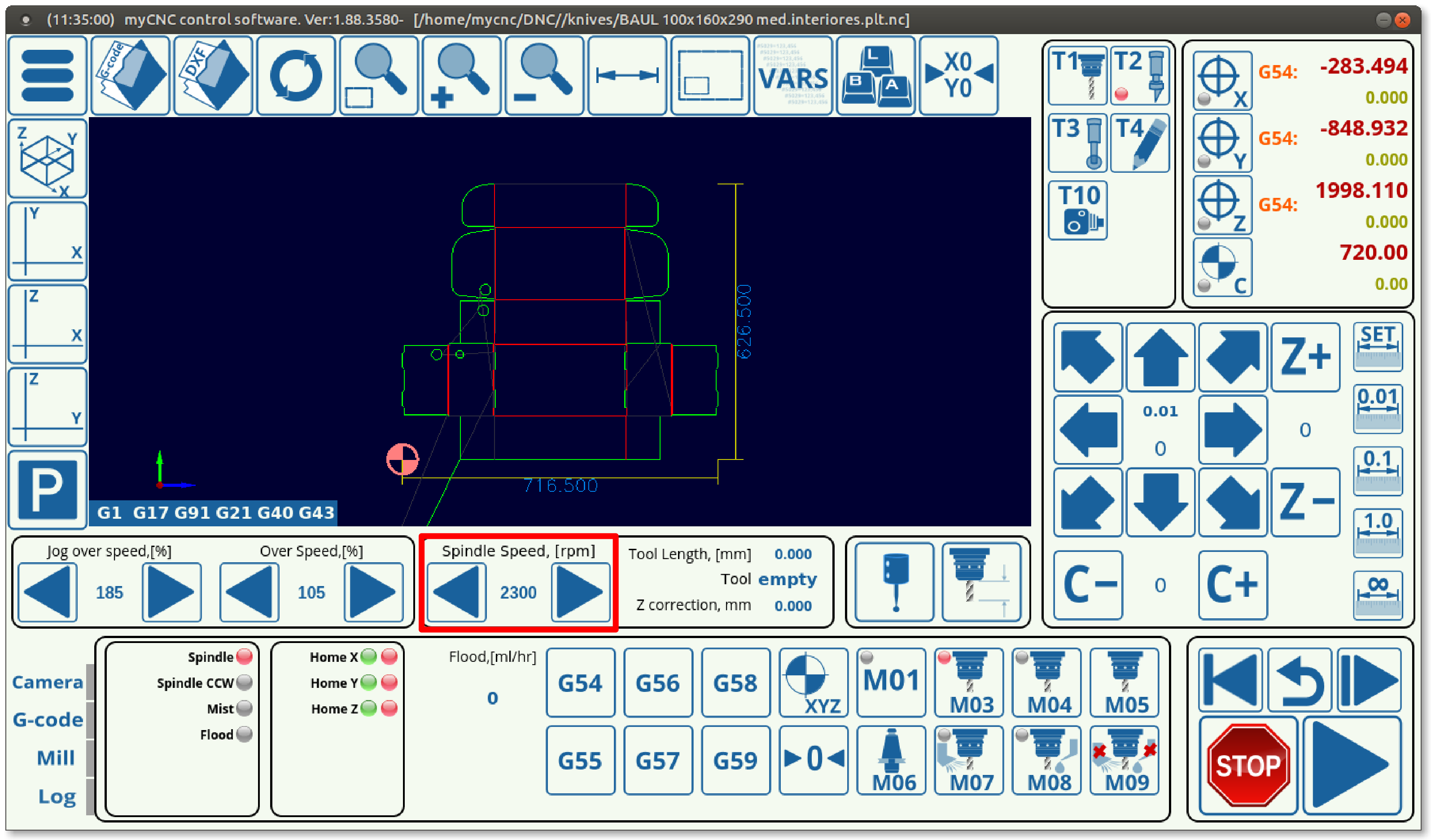

The eparam value here is taken from the spindle speed indicator on the main screen of the myCNC X1366 series profiles:

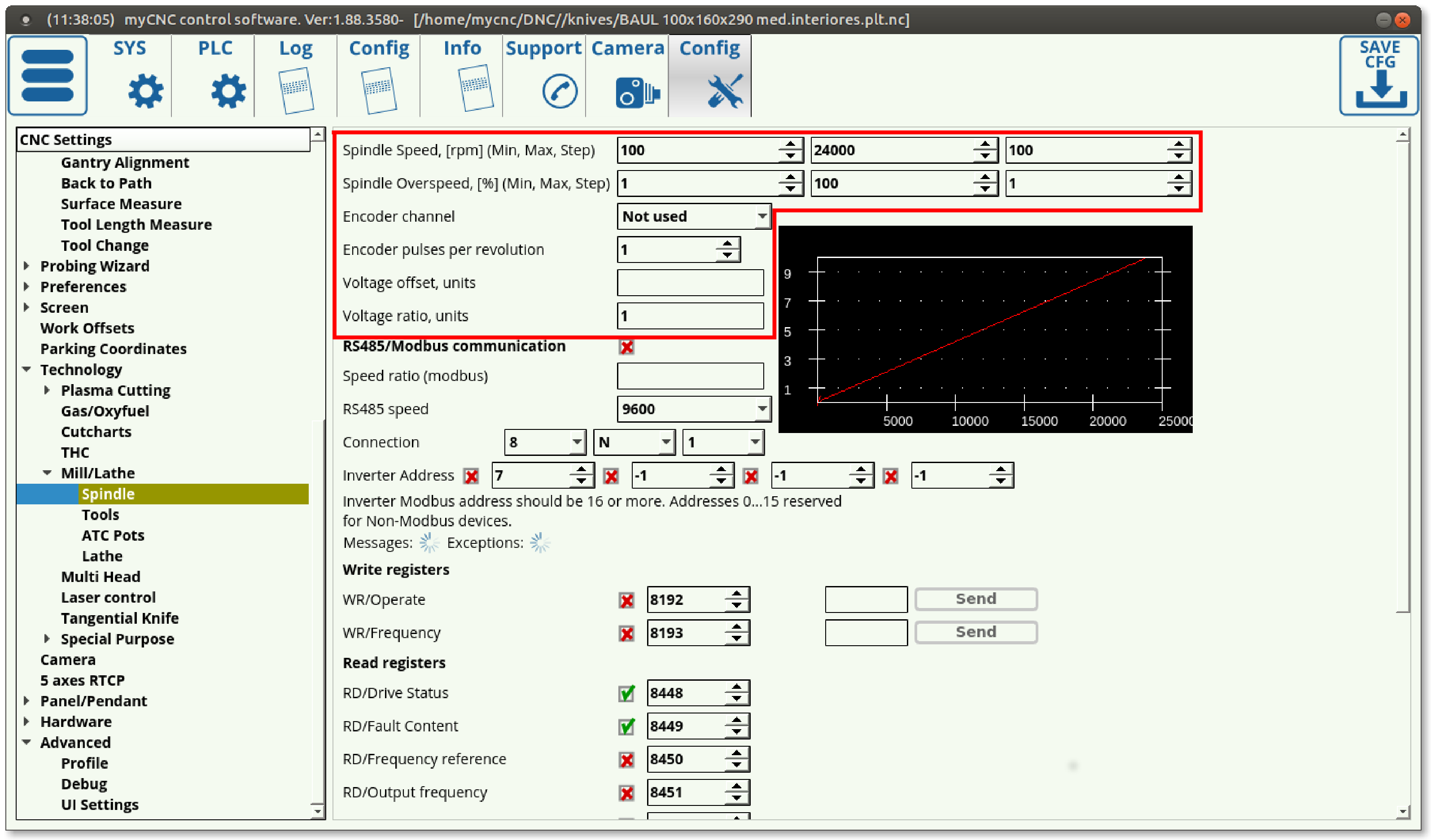

This value is taken from the field above and converted to a necessary output value using the settings provided in the Settings > Config > Technology > Mill/Lathe > Spindle configuration dialog: