myCNC Software Main Features

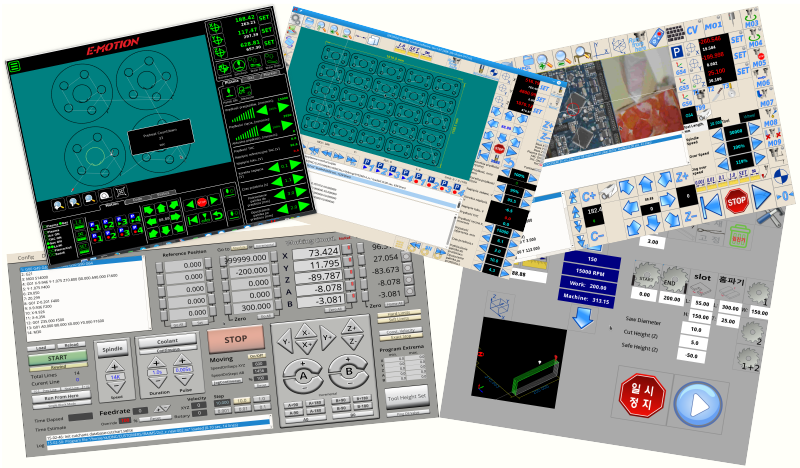

myCNC is multi-tasking and multi-platform CNC Control Software working under MS Windows (7, 8, 10), Linux, Embedded Linux Operating systems. myCNC can be run on Desktop PC, Industrial PC, Laptop or Single Board Computer (SBC) like Raspberry Pi 2/3, Odroid-C2/XU4, Asus Tinker Board, Rock64, Cubieboard2 and some others.

myCNC Control features

- 6 Axes motion control with S-curve speed profile for smooth machine motion;

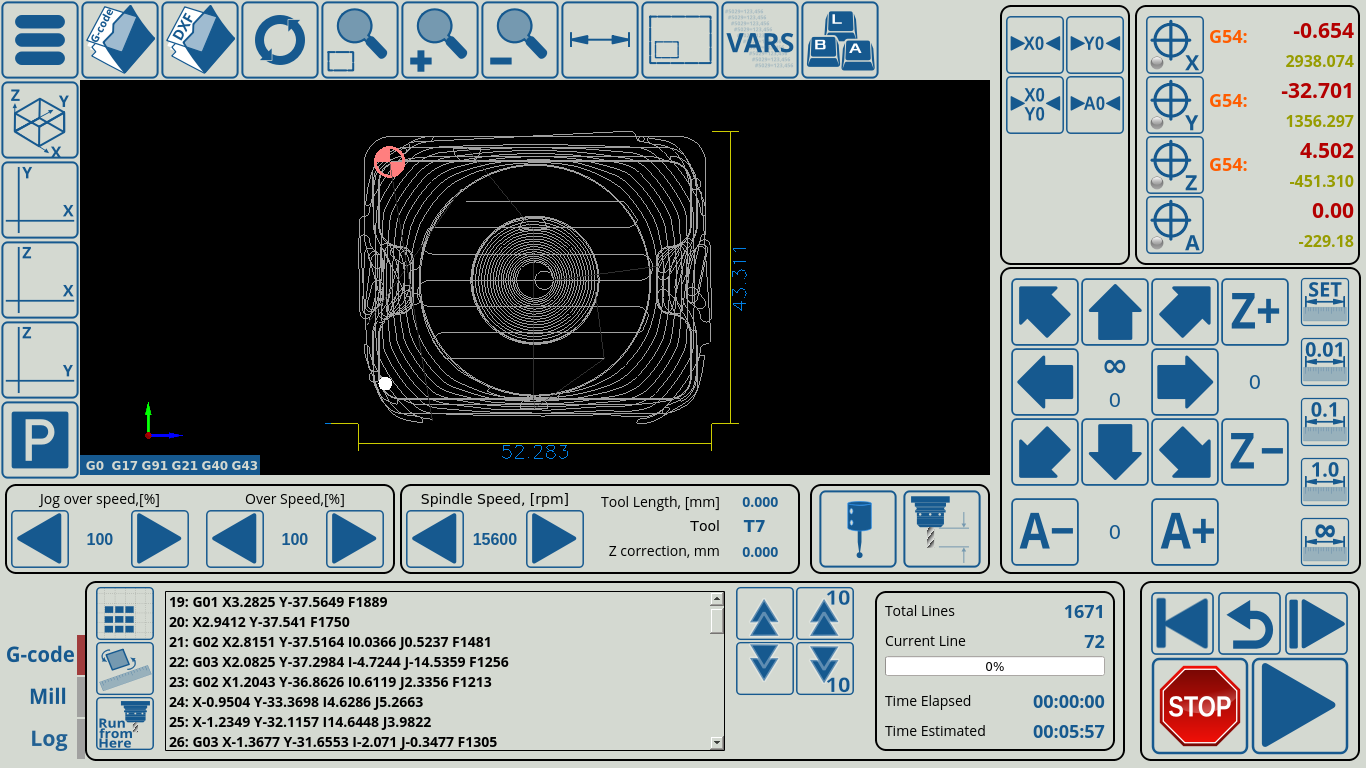

- G-code with Macro Language extension support;

- Built-in PLC controllers and built-in PLC Builder IDE for flexible peripherals control;

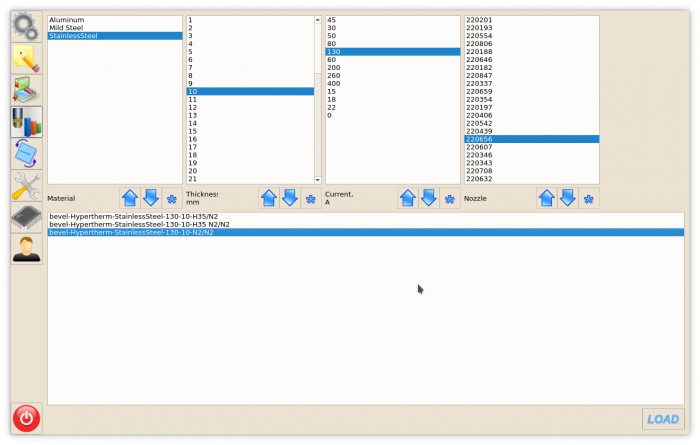

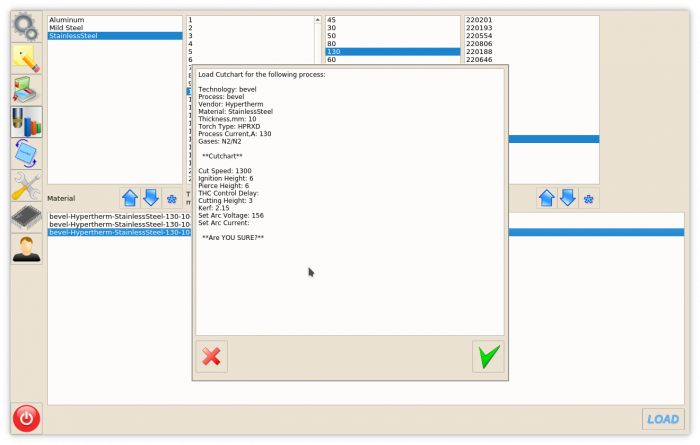

- Support special-purpose G/M codes for wide range of applications - mill, lathe, routers, tangential knife, plasma, oxyfuel, laser cutting, Torch Height Control (THC), ATC

- Big G-code files up to 1GB supported

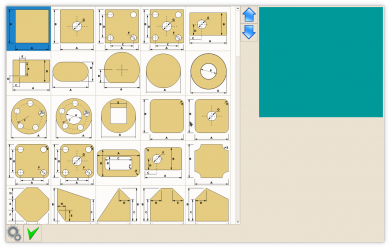

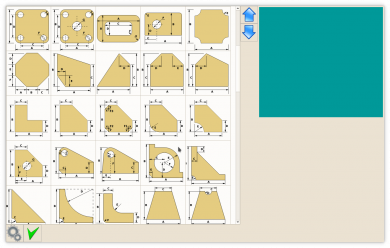

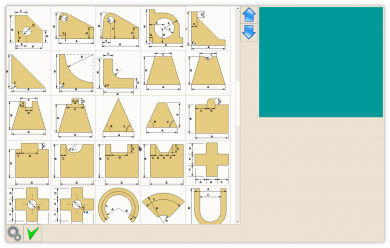

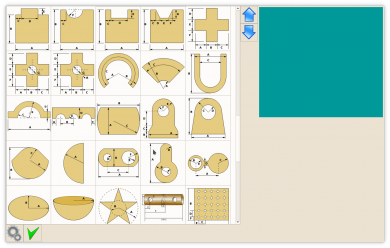

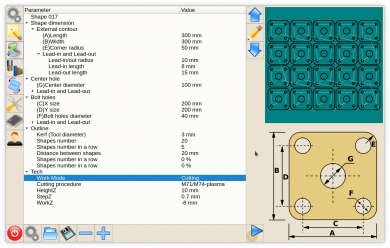

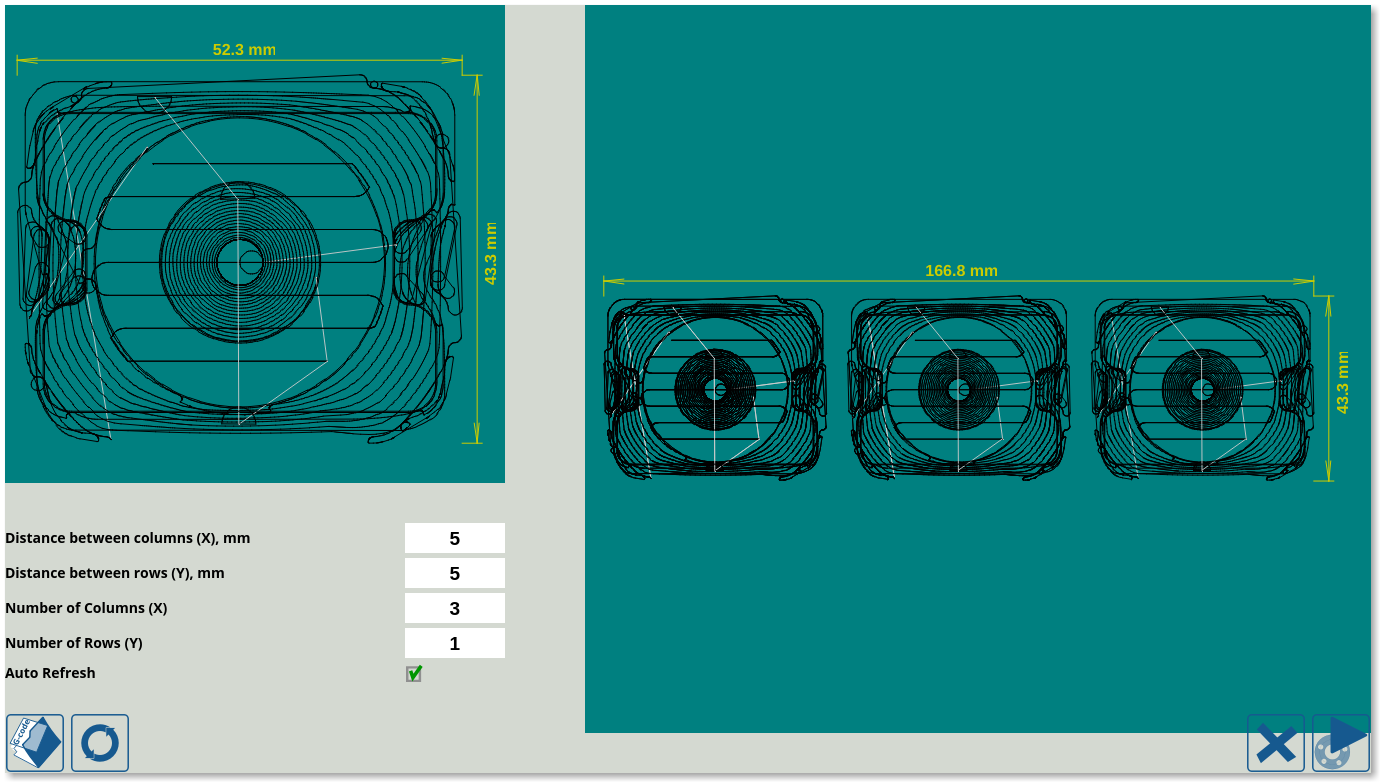

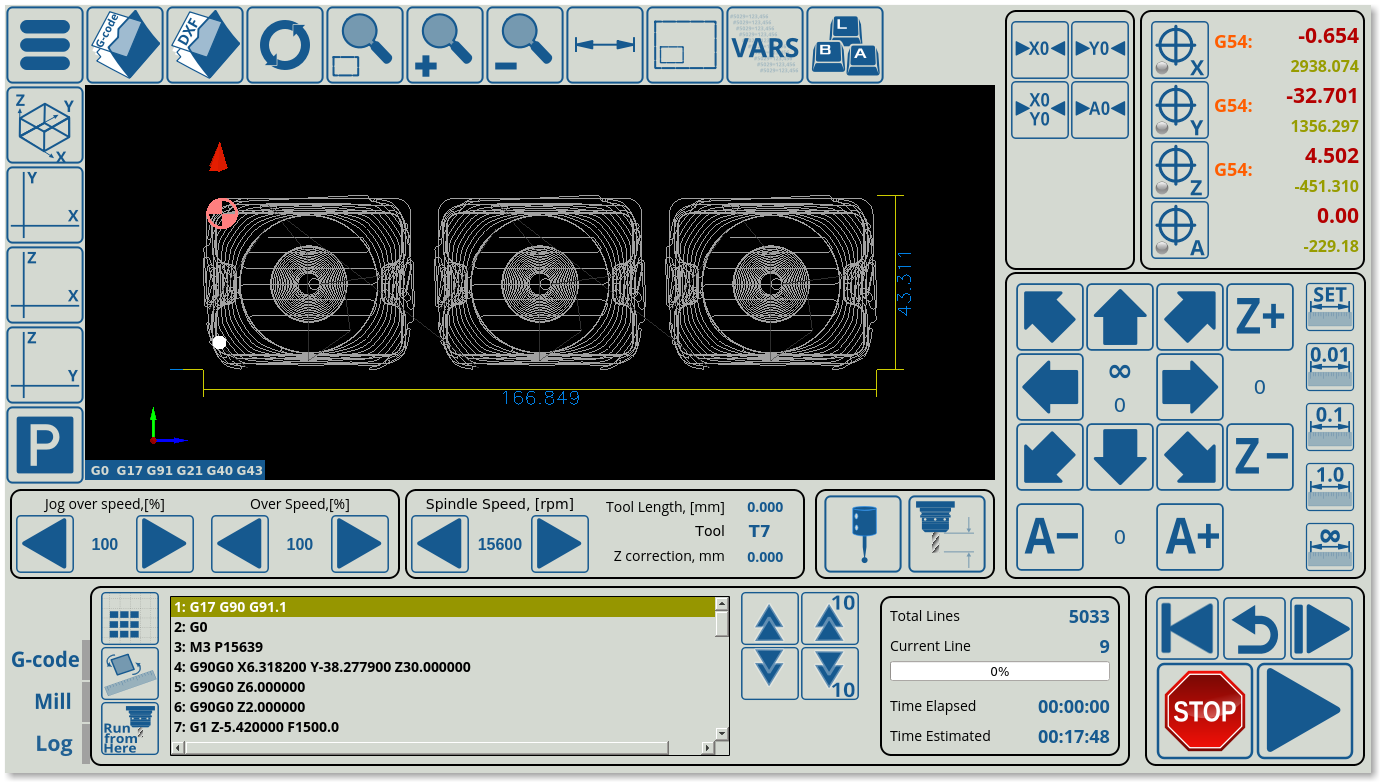

- Shape Library - has a good set of parameterized shapes with row&column nesting features and several cutting technologies supported (plasma-gas cutting, engraving, multi-pass cutting). New shapes can be easily added to the Shape library by customers, examples available

Row and column Nesting for library Shapes

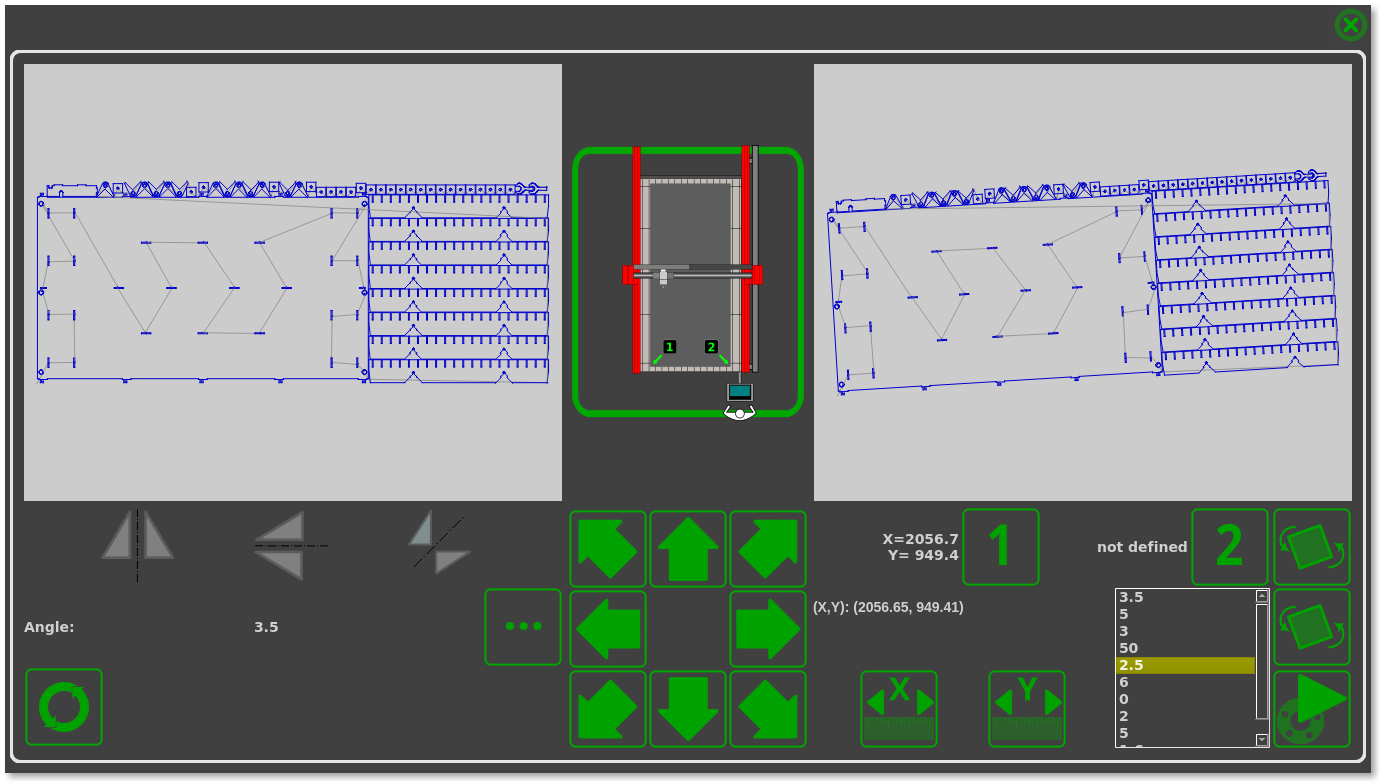

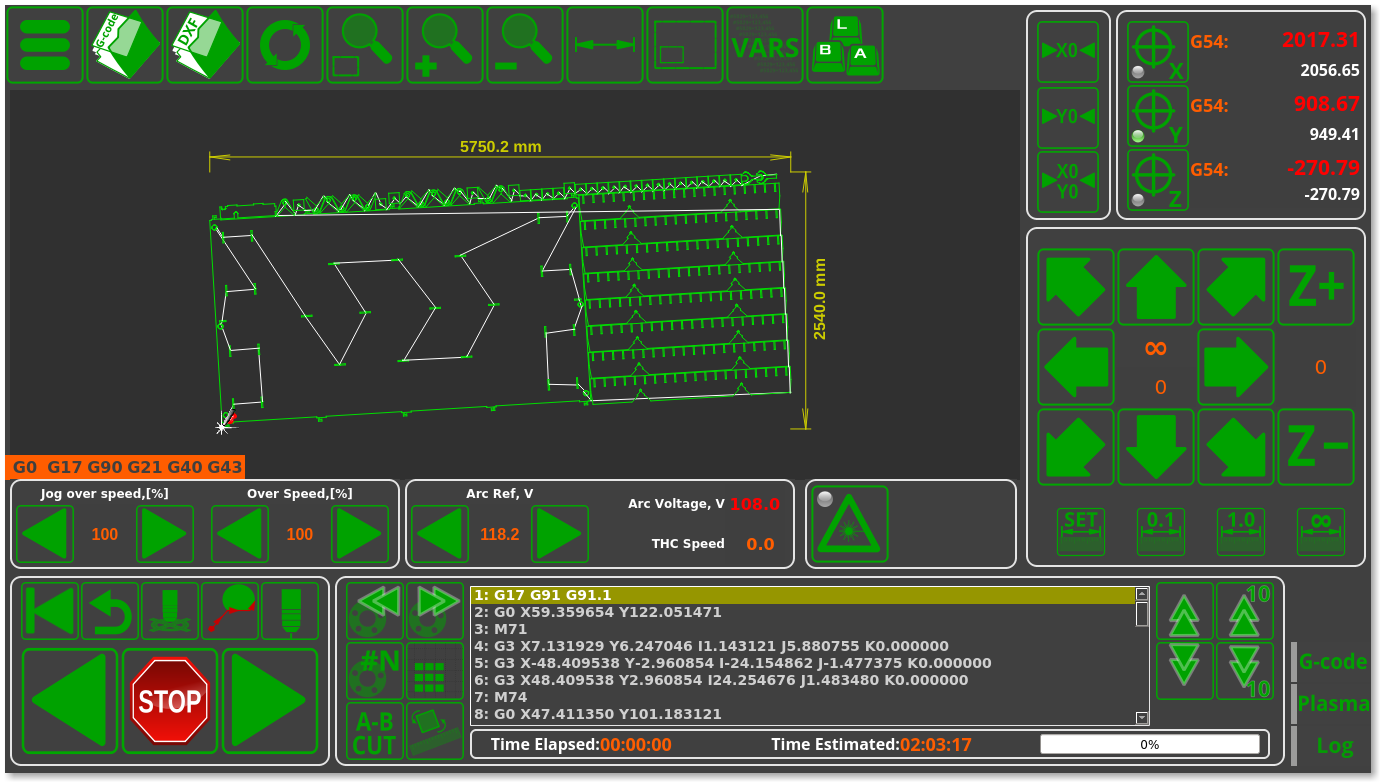

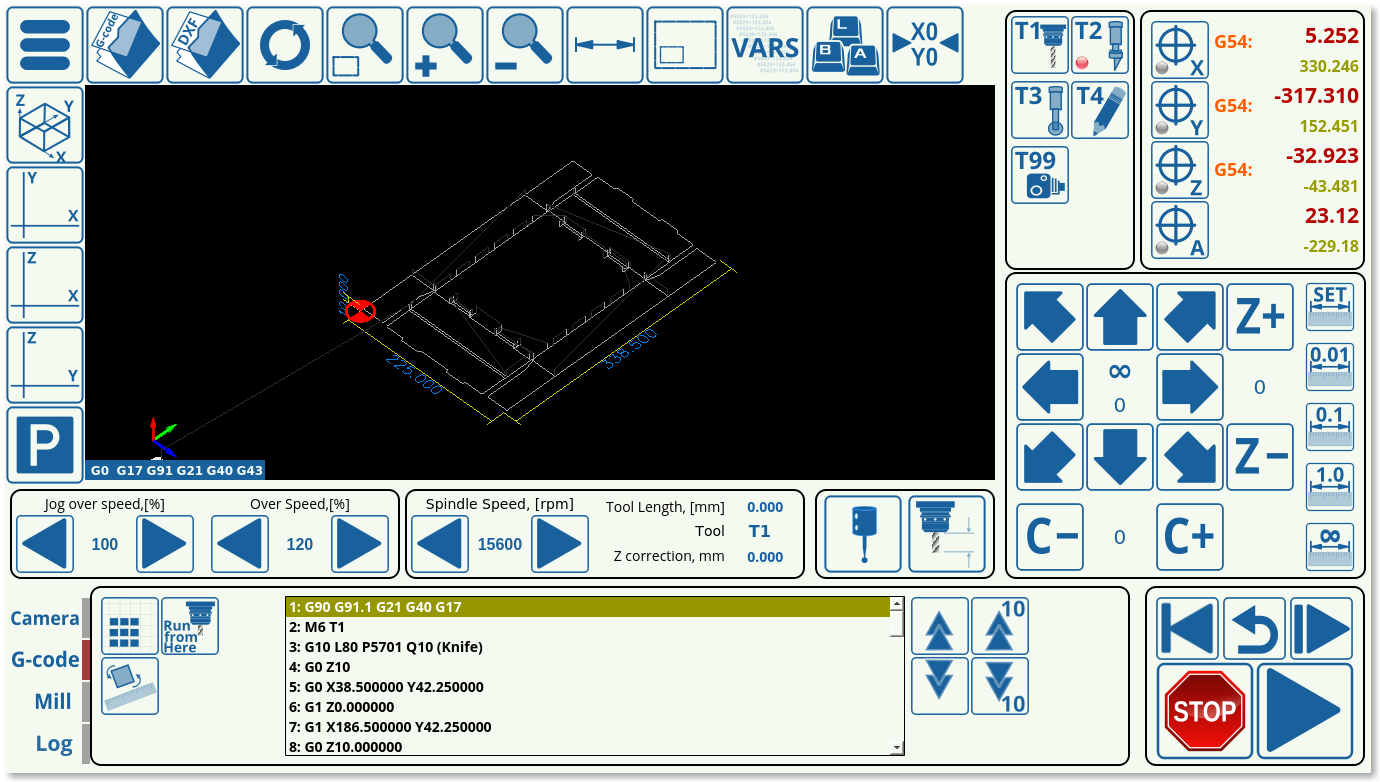

Different cutting technology supported in Shape Library - like automatic insert Lead-In/Lead-outs for Plasma/Gas Cutting or Multi Pass cutting and Engraving for Routers/Mill - G-code program Rotation, Mirror transformations - g-code program can be mirrored relative to (x=0), (y=0) or (x=y) lines or rotated for given angle or to angle calculated from 2 base points. This feature widely used for heavy plasma/gas cutting machines, routers, but might be useful for mill machines as well.

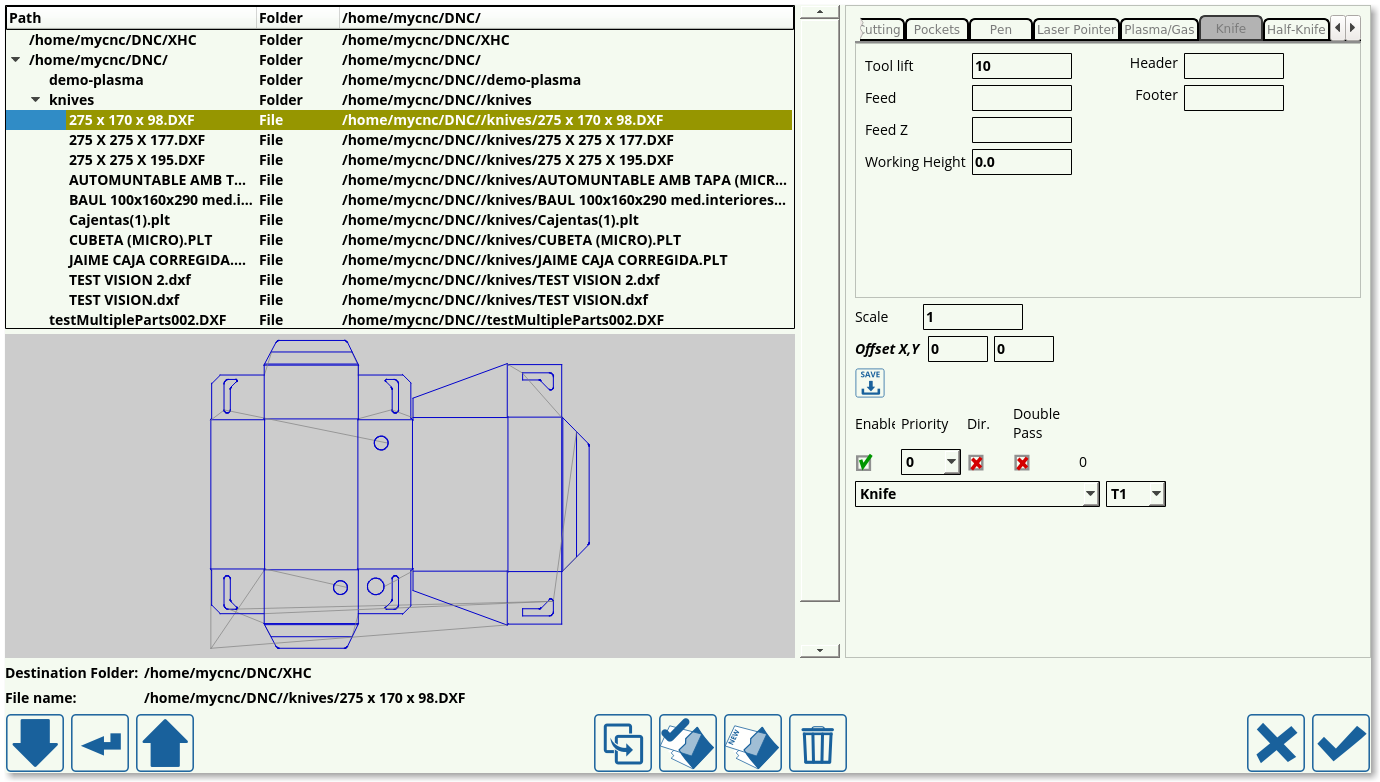

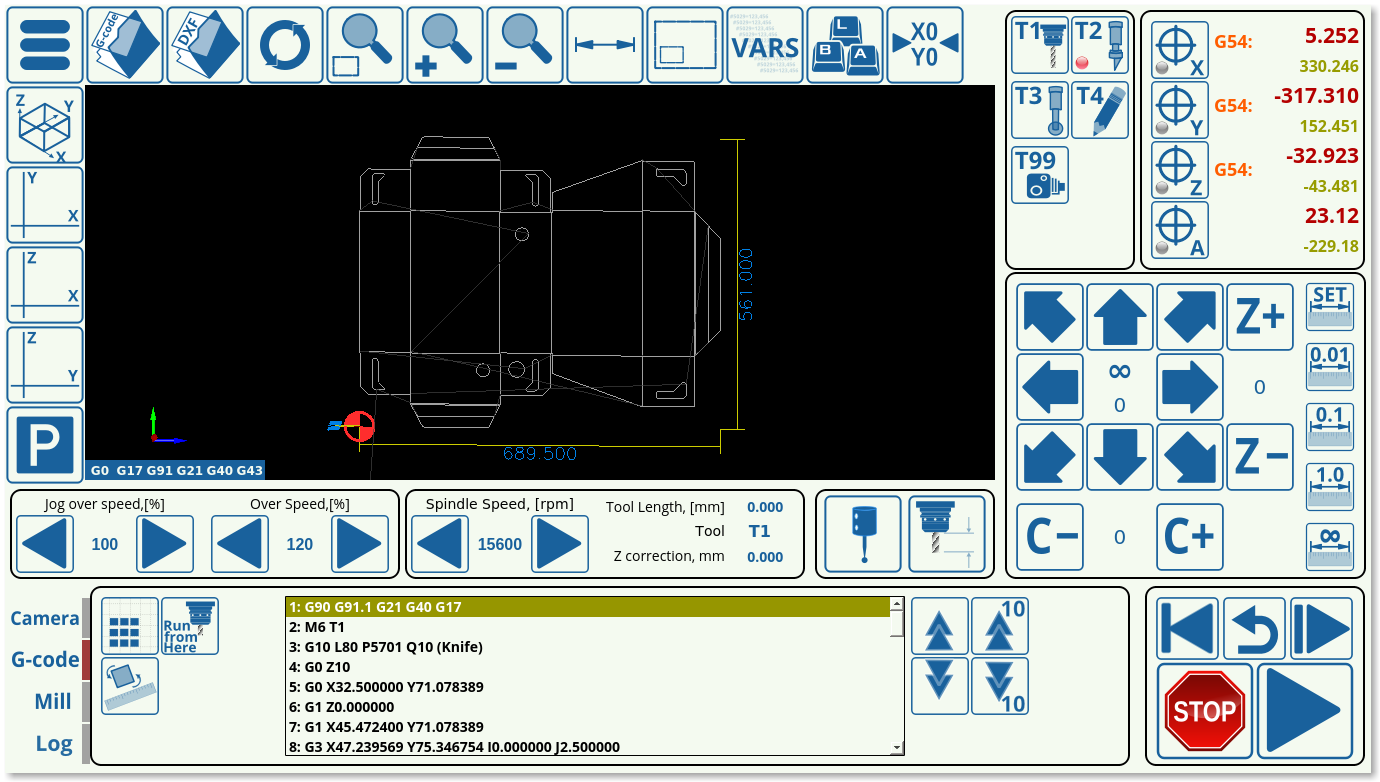

- DXF/HPGL import and convert to G-codes with multi-head multi-technology support. Every layer of DXF file (or every Pen for HPGL) can be assigned to different technology and myCNC control will generate G-code accordingly:

- Add Lead-in/Lead-outs for Plasma-Gas-Laser cutting

- Add Lift Up/Cut down Tool for each Engraving contour

- Add Several Cut Passes for Multi-Pass Mill

- Generate Pockets for Pockets Layer

- Add Knife Lift Up/Cut down codes for Tangential Knife Layer

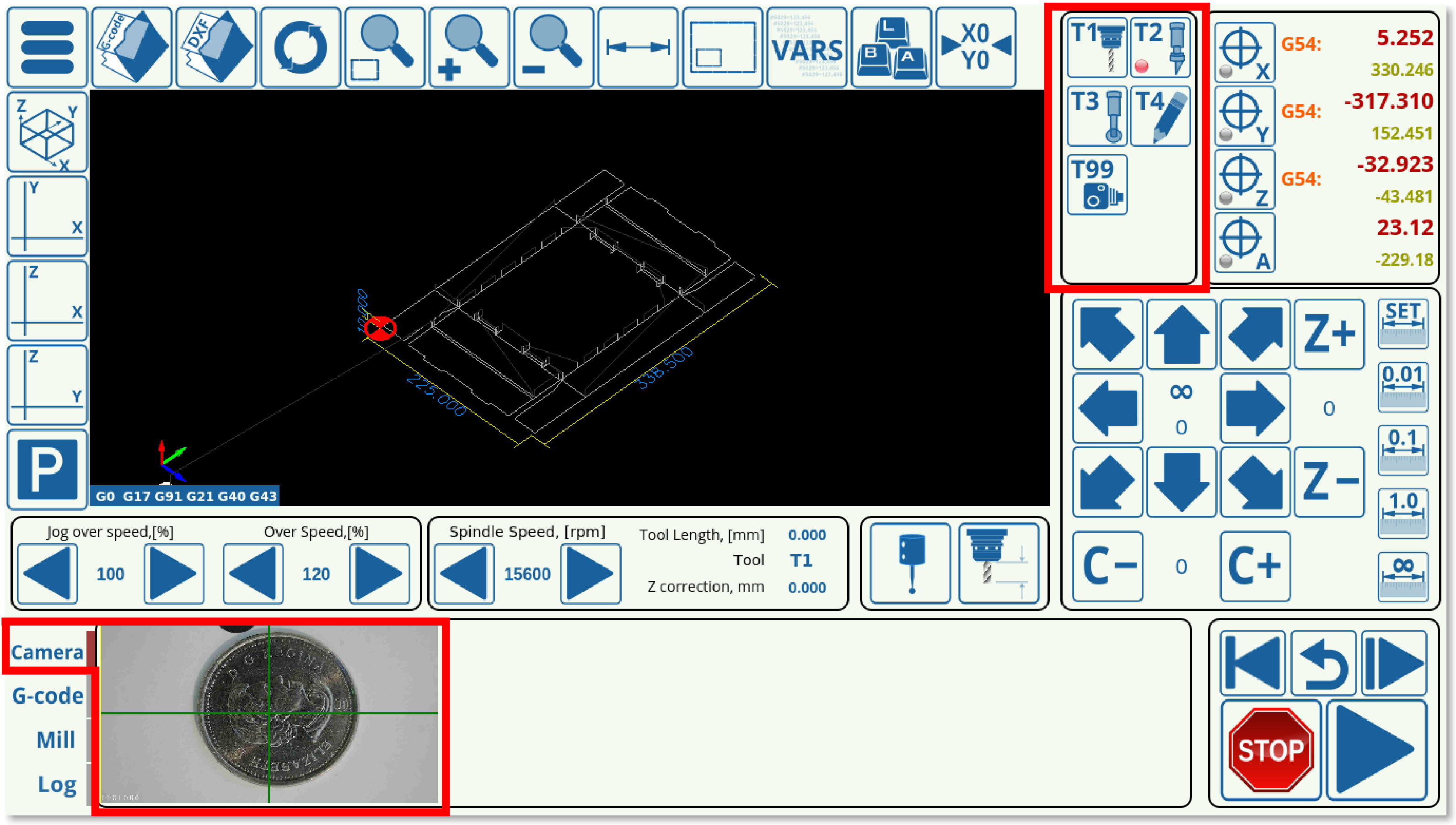

- Add Computer Vision codes for Camera Layer

ATC (Automatic Tool Change) is supported for any myCNC control board. myCNC contains Macro Wizard to generate Tool change macros for different kind of Tool changers (linear, drum/rotary, chain)

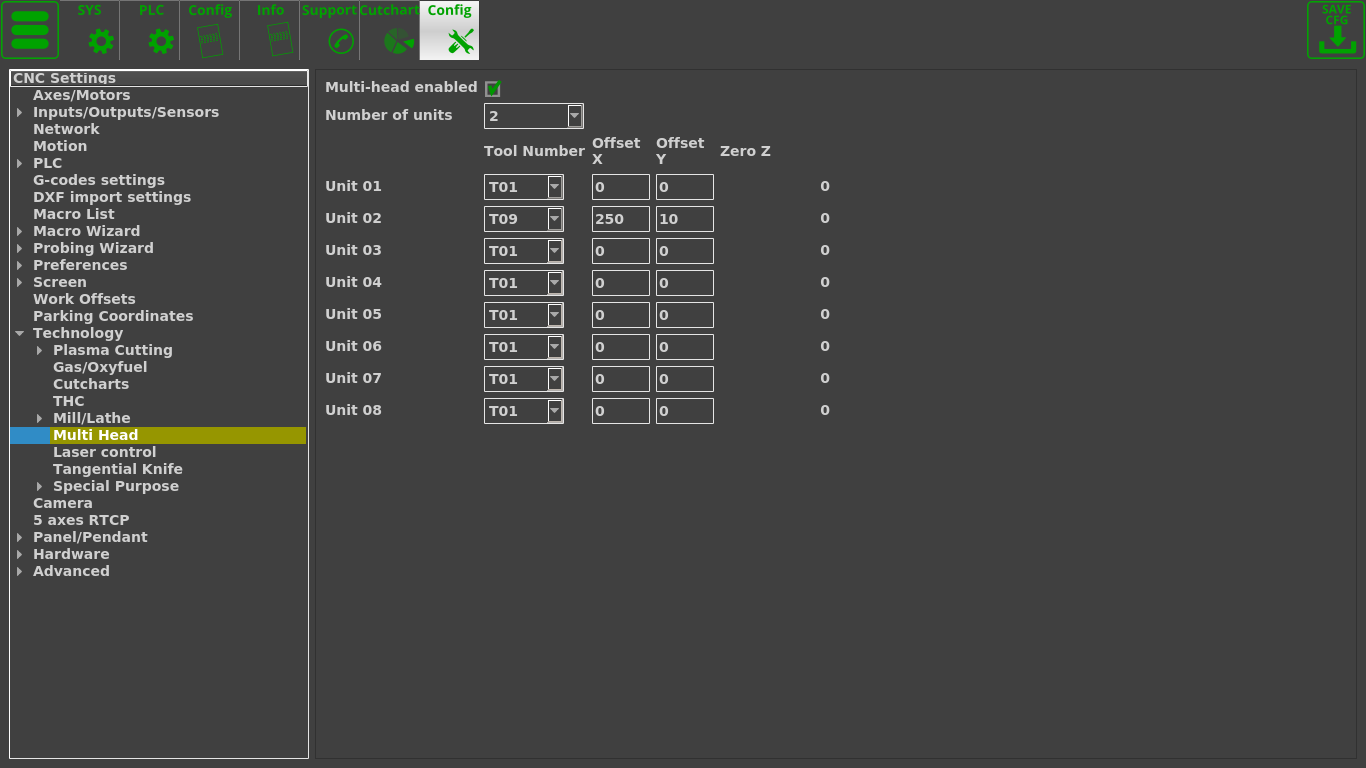

Multi-Tool support. If several tools is installed on machine head myCNC control software can handle switching tools procedure and apply tool offsets just like standard M6/Tool change procedure

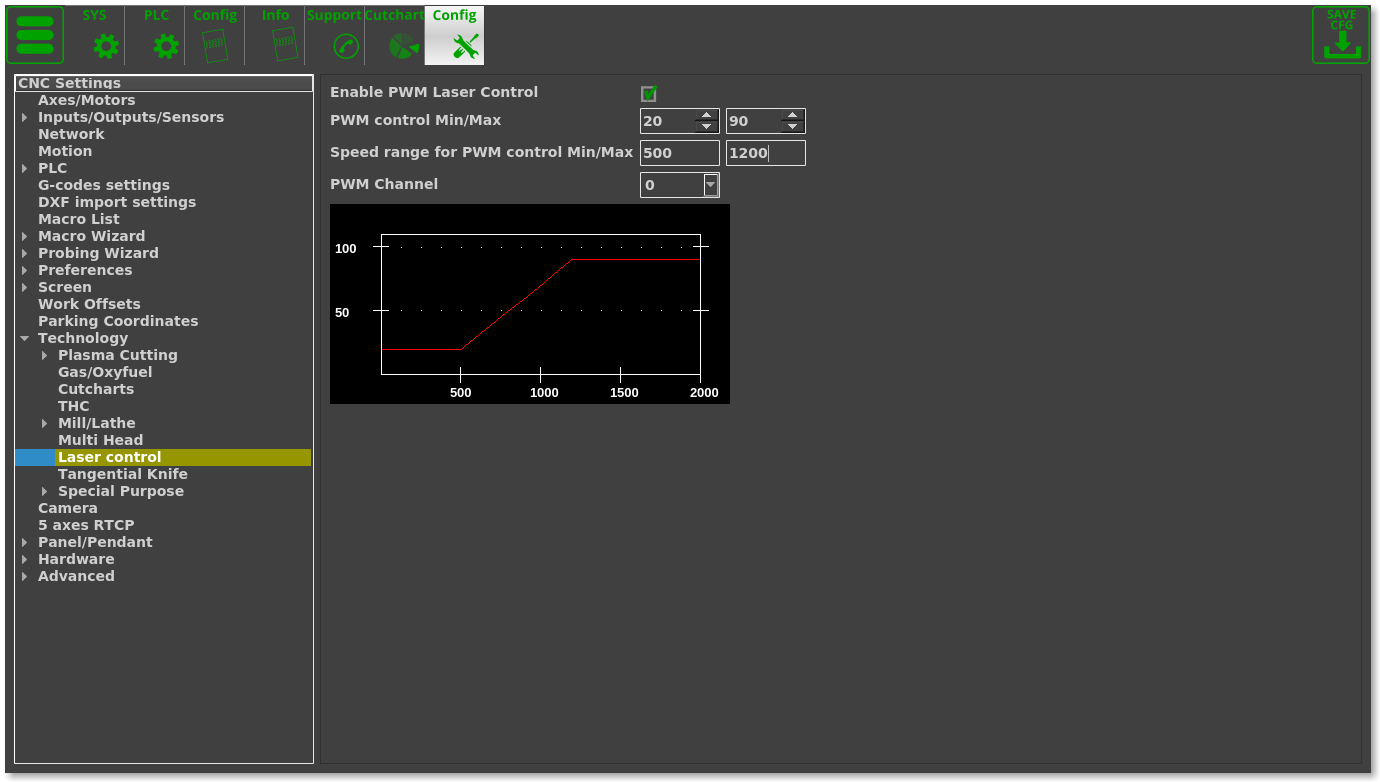

Laser Strength Control. myCNC software allows the user to adjust the laser strength depending on the speed with which the laser beam is moving across the surface of the material. This is highly useful to eliminate overheating from the laser beam that would otherwise occur at corners and parts of the program where the beam slows down.

Wireless Pendant control support. myCNC supports a number of Wireless Pendant Controls

Flycut process allows to go through the laser cutting/engraving process much faster than the conventional setup when thin materials are used. The flycut process can maintain precision up to a 0.1 mm at working speeds up to 100 meters/minute by syncing the laser cutting/movement processes. The M64/M65 codes turn the corresponding exit ON and OFF, while M164/M165 allow for on-the-fly pulse-width modulation.

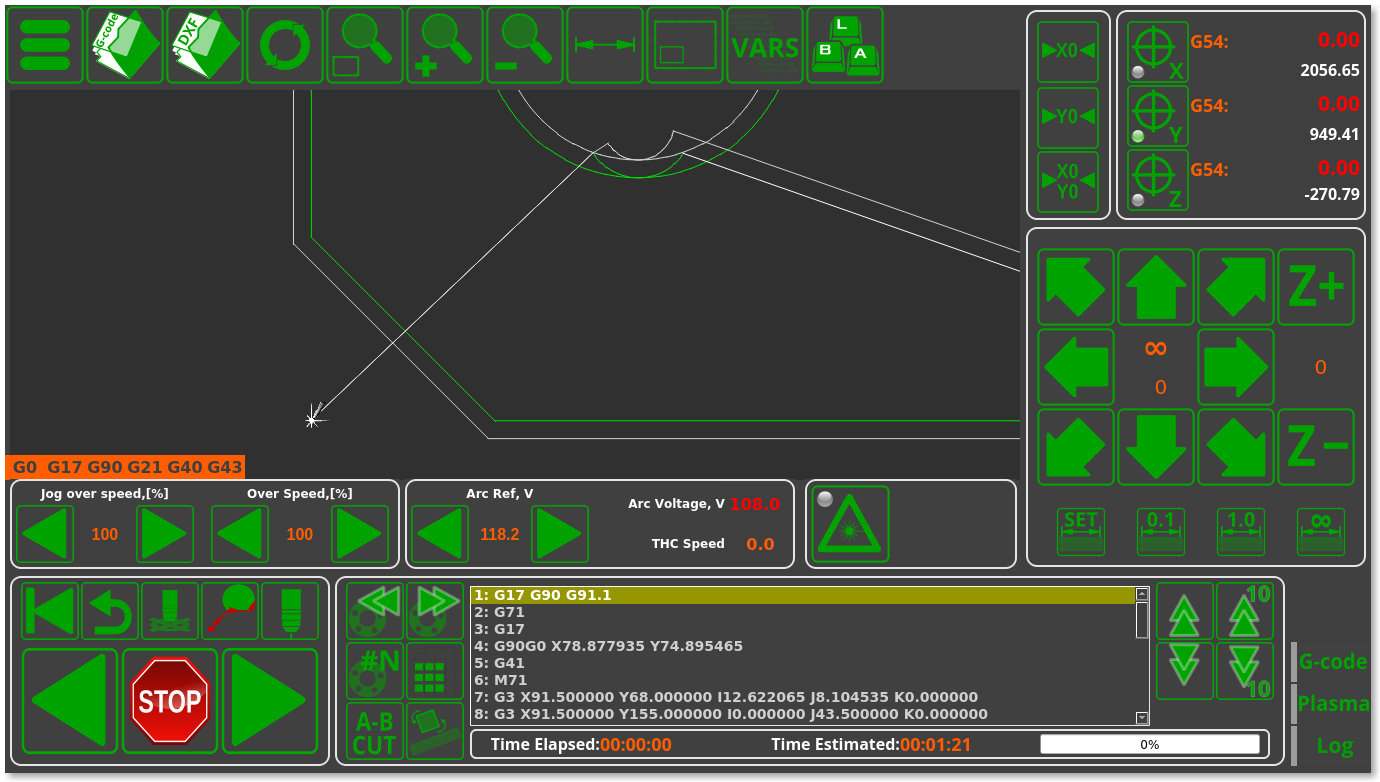

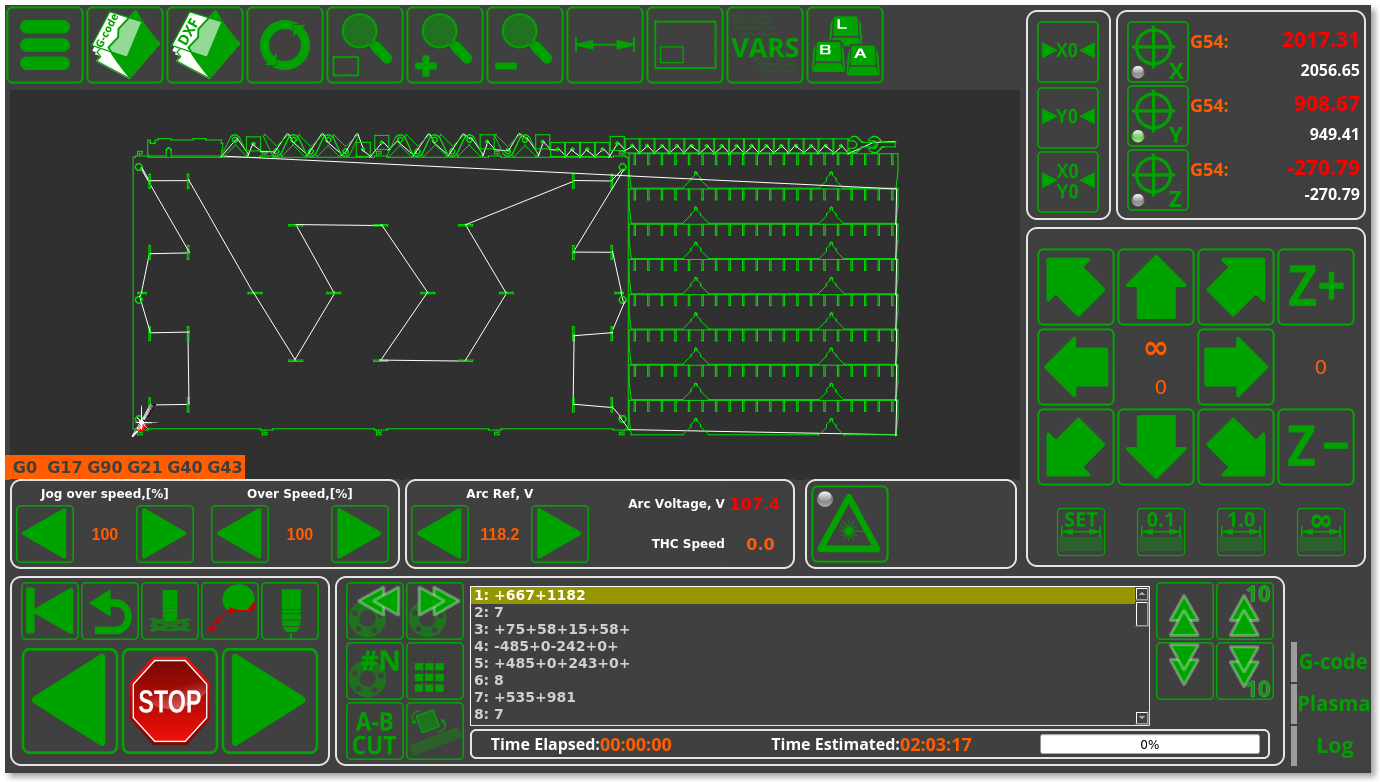

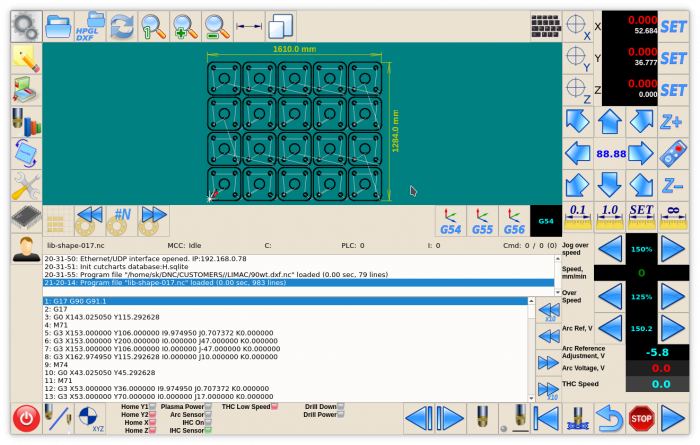

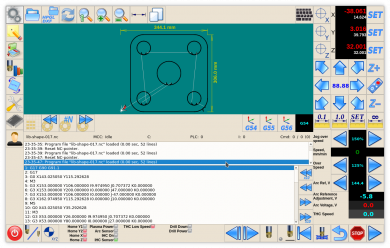

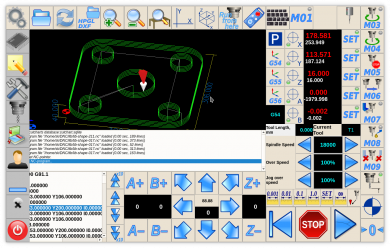

Advanced 2D/3D visualization, real-time IO monitoring,

Row and Column Nesting. myCNC able to multiply g-code file by given number along X and Y axes.

Tool Radius Compensation with visualization. myCNC does Tool Radius compensation according G40-G42 codes and Tool Table and able to show results on Visualization widget to visual control.