This is an old revision of the document!

Table of Contents

MyCNC Setup Examples

How to setup Tangential Knife Cutting

MyCNC control has built-in tangential knife control

Tangential knife control is activated by writing “1” to Global Variable #7005 (GVAR_TANGENTKNIFE_ENABLE)

If Tangential control is activated 2D toolpath programming is enough to make tangential knife cutting. myCNC control software automatically -

- Calculates the angle of next motion;

- Lifts up the knife to safe height;

- Rotate knife accordingly next XY motion direction;

- Moves down knife on working height.

How to setup Lathe/Turning machine

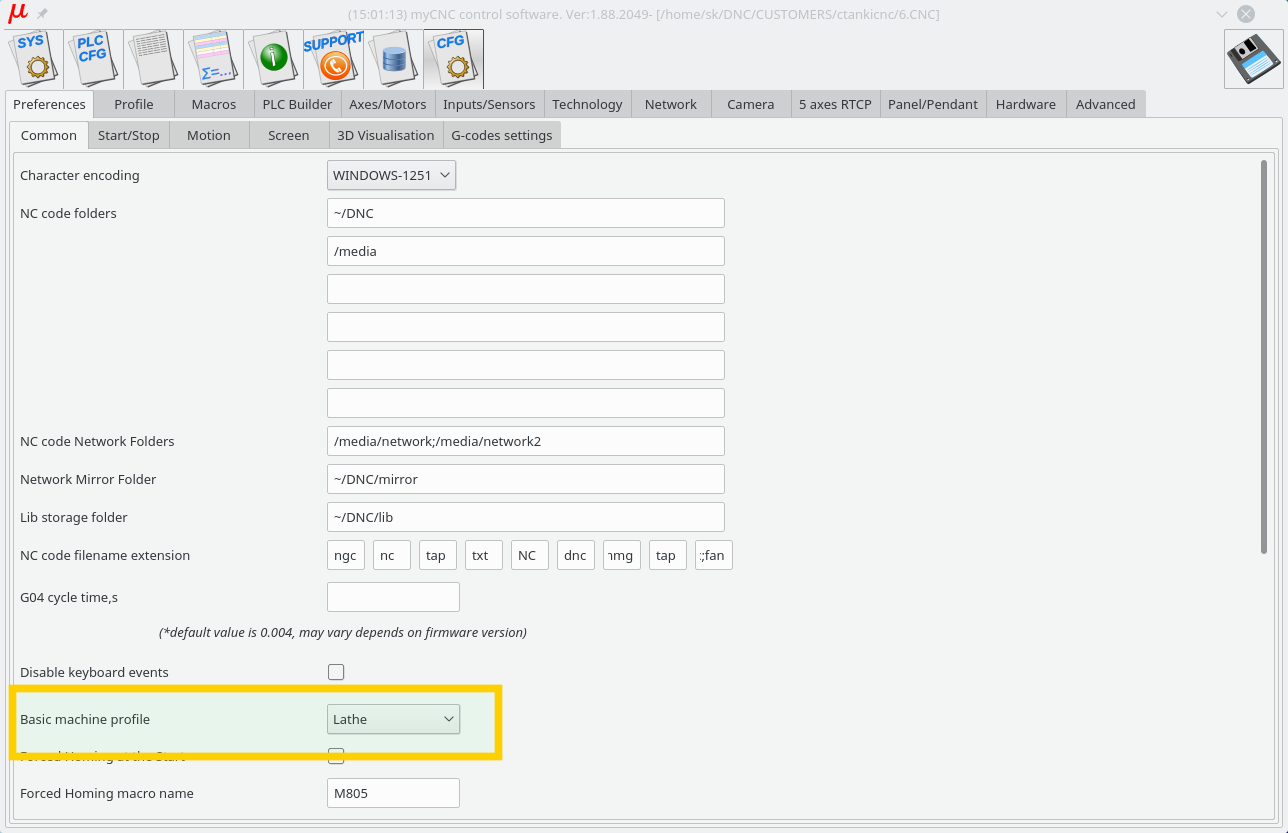

1. Select Basic profile as “Lathe” in Cfg - Preferences - Common dialog

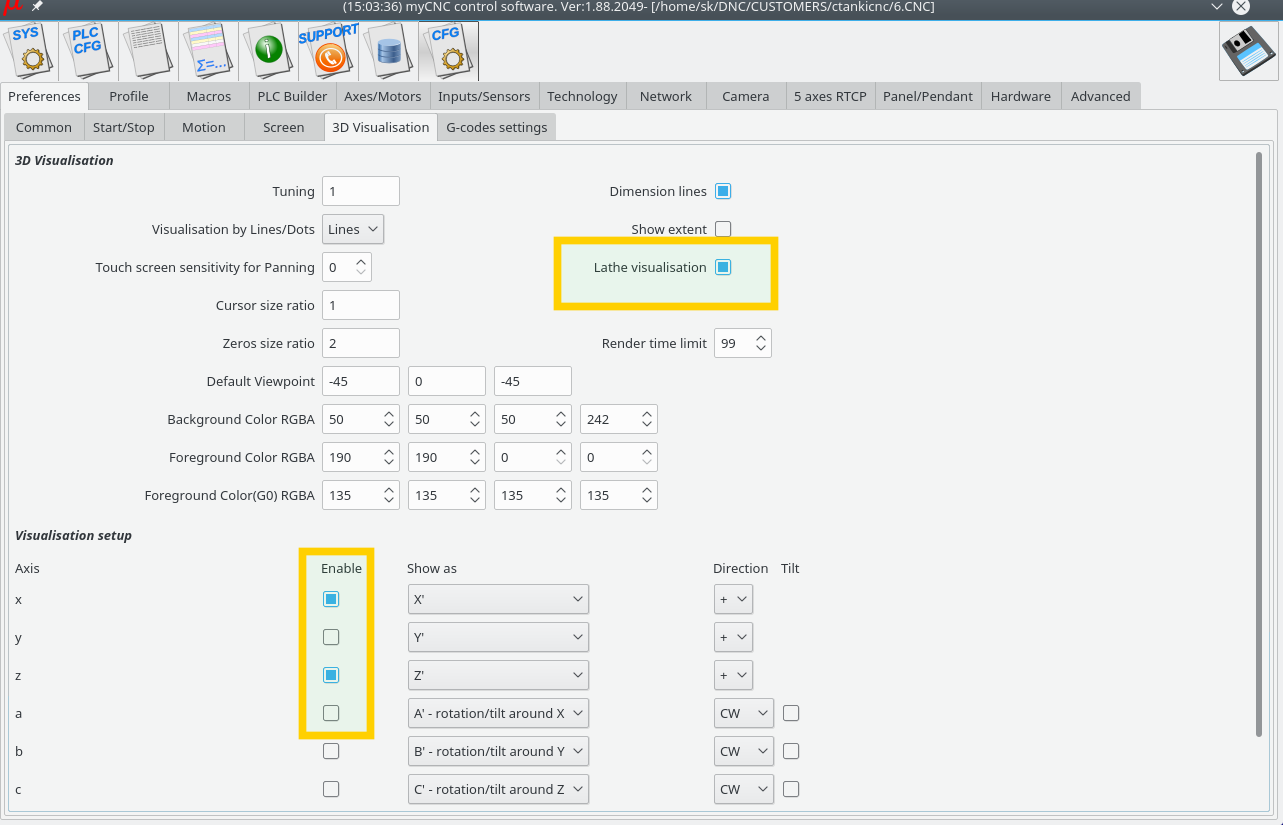

2. Select “Lathe Visualisation” in Cfg - Preferences - 3D visualisation configuration dialog

3. Select axes X, Z for visualisation and deselect the rest axes.

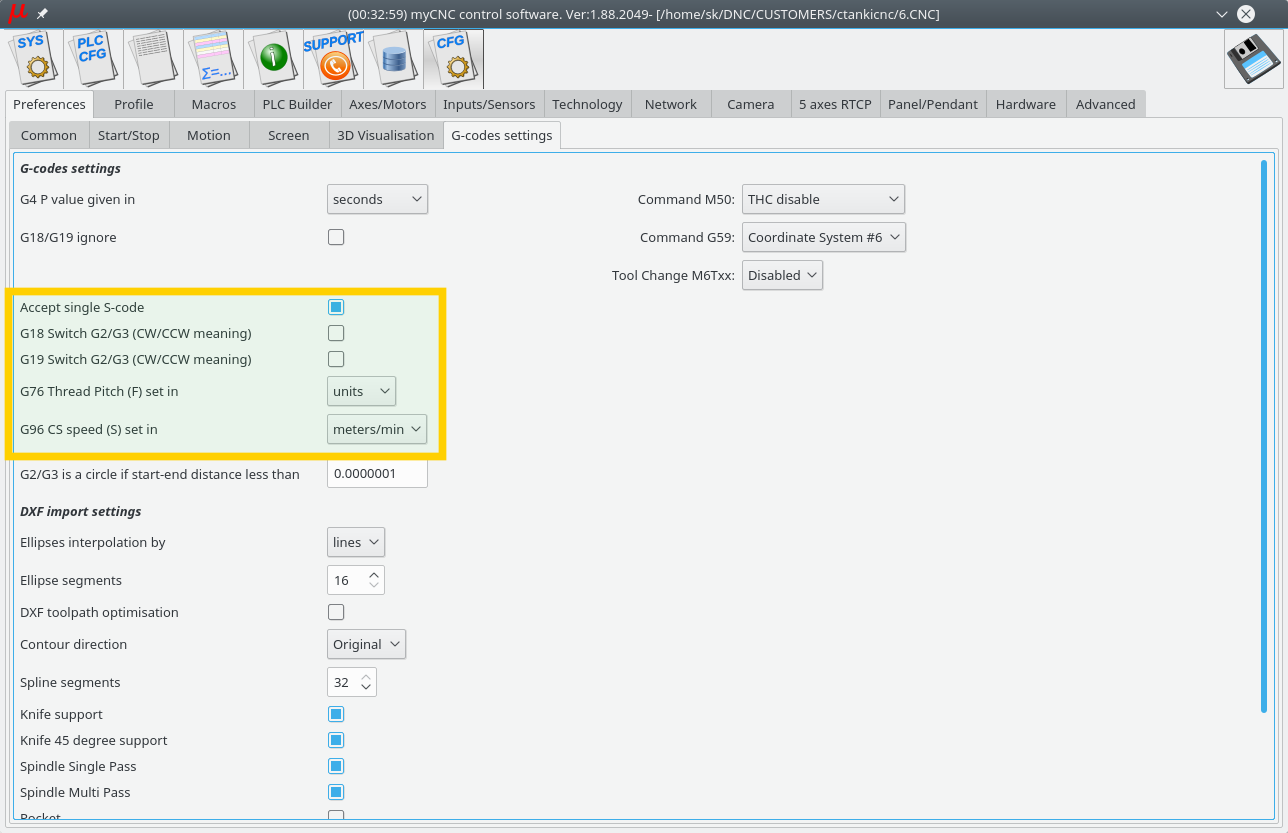

4. Check G-code settings related to Lathe operations in Cfg - Preferences - G-codes settings configuration dialog

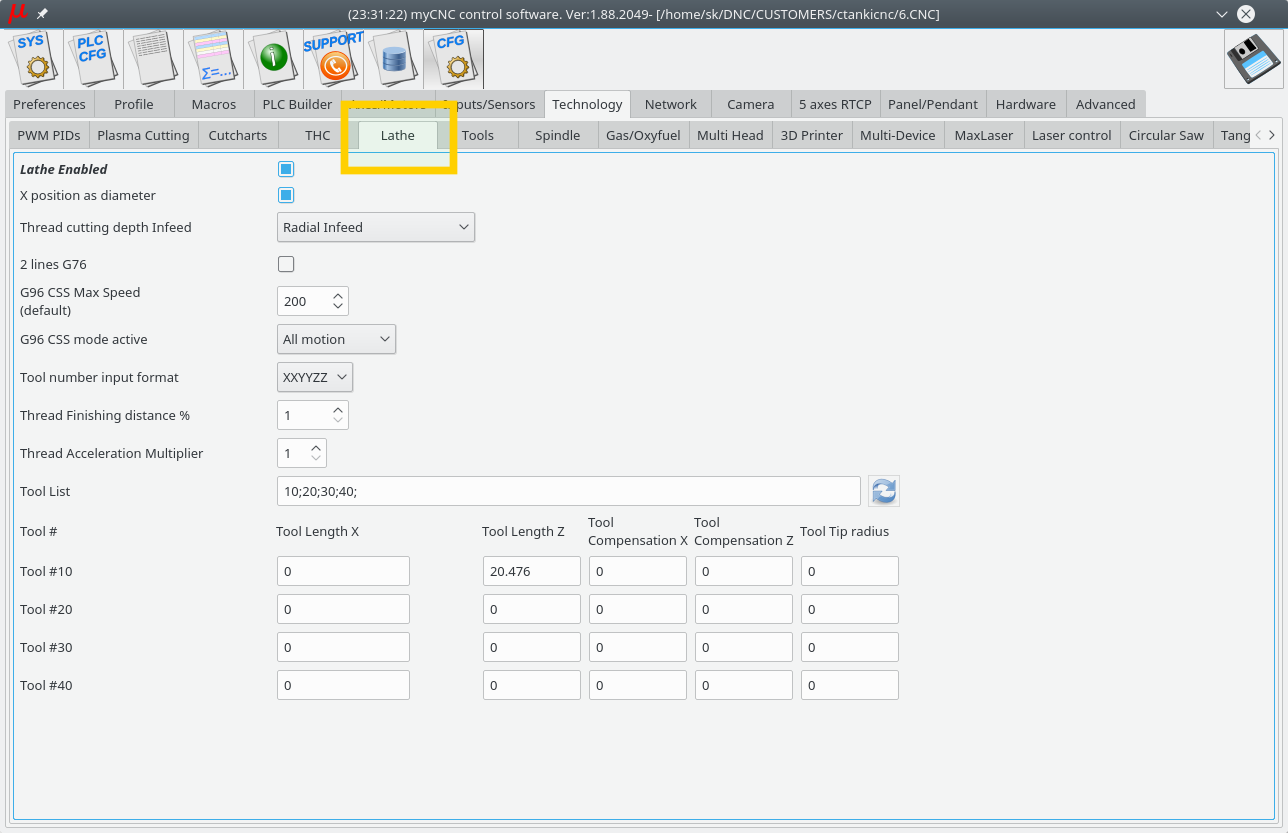

5. Goto Cfg - Technology - Lathe configuration dialog and setup appropriate settings

How to setup Multi-Tool router

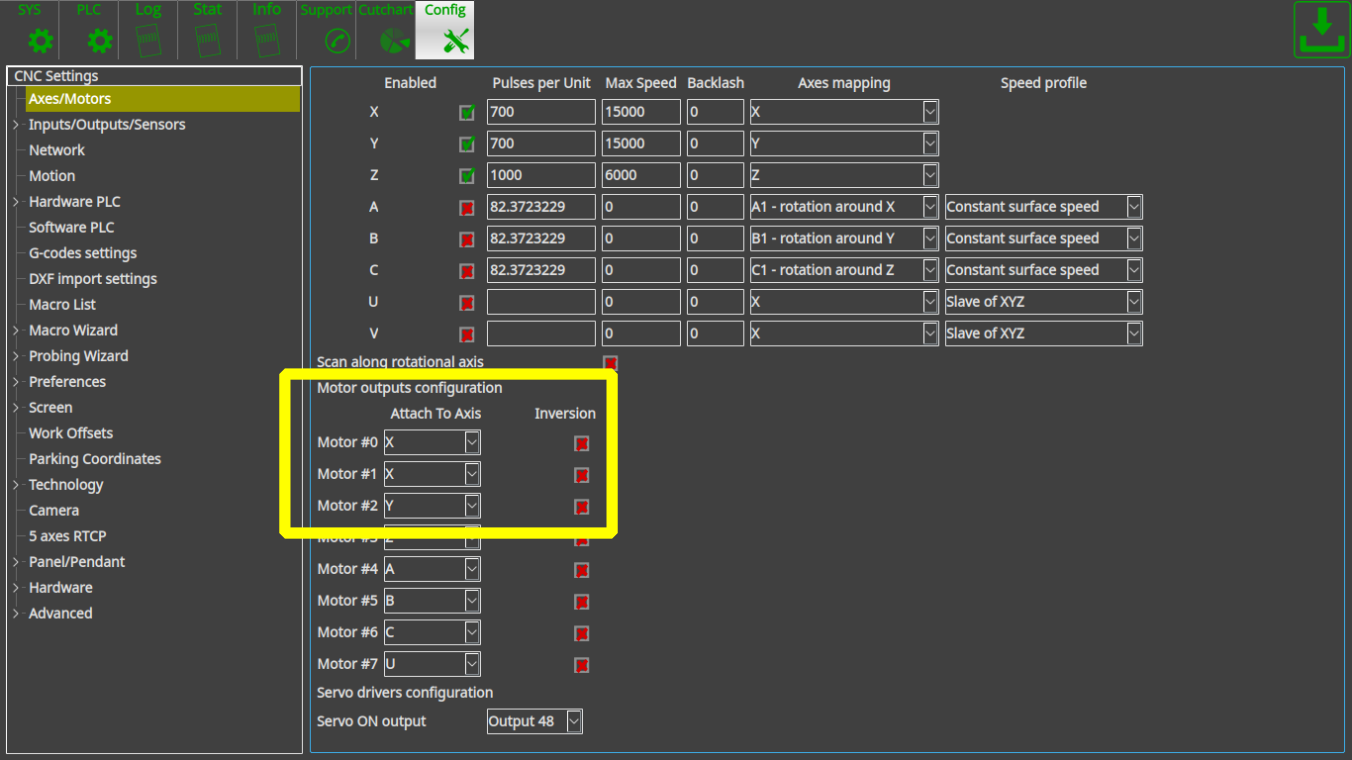

We will put here some process of setup multi tool router. The router has -

- 2x motors on X axes.

- 2x separate spindles installed on separate Z heads.

- Tangential knife head.

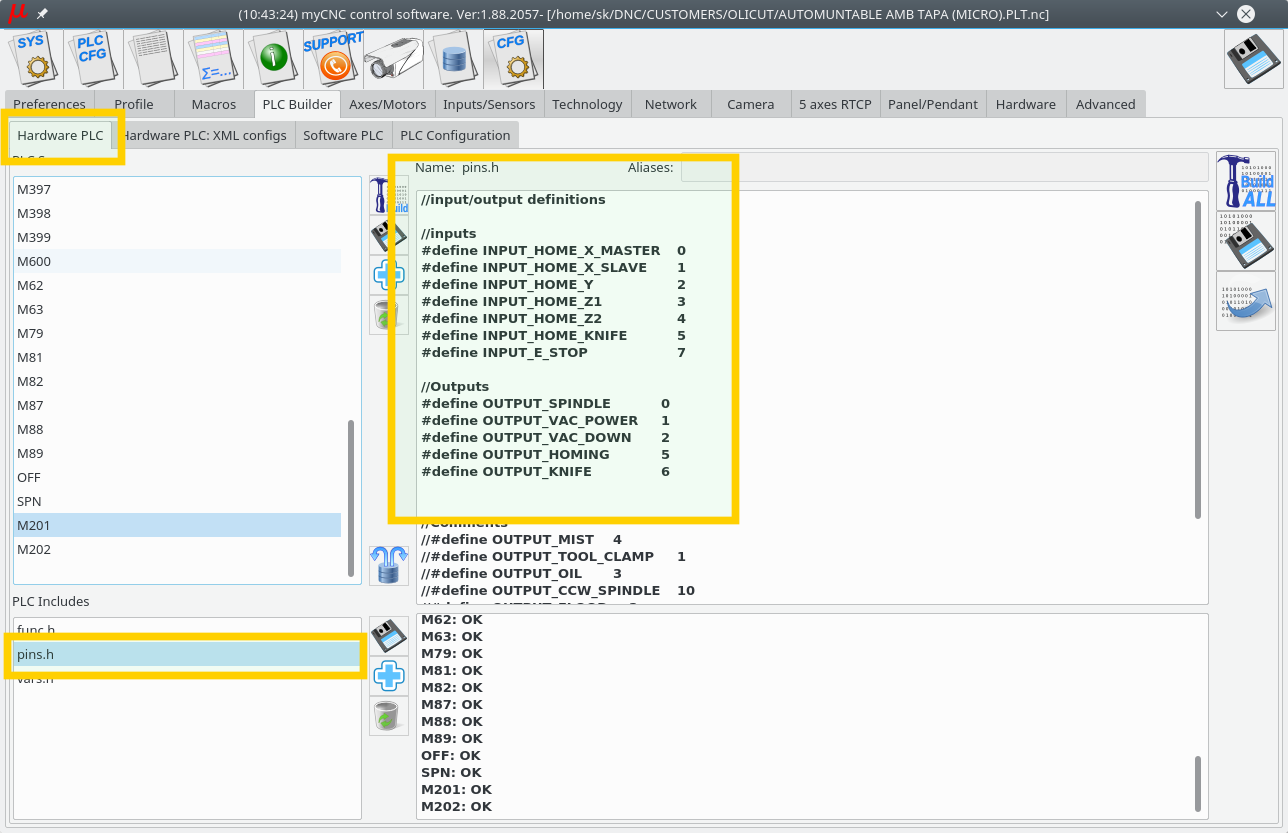

1. Inputs/Outputs assignment described on “pins.h” include file in Hardware PLC Builder area -

- pins.h

//input/output definitions //inputs #define INPUT_HOME_X_MASTER 0 #define INPUT_HOME_X_SLAVE 1 #define INPUT_HOME_Y 2 #define INPUT_HOME_Z1 3 #define INPUT_HOME_Z2 4 #define INPUT_HOME_KNIFE 5 #define INPUT_E_STOP 7 //Outputs #define OUTPUT_SPINDLE 0 #define OUTPUT_VAC_POWER 1 #define OUTPUT_VAC_DOWN 2 #define OUTPUT_HOMING 5 #define OUTPUT_KNIFE 6

2. How to switch between spindles (Z1/Z2) heads.

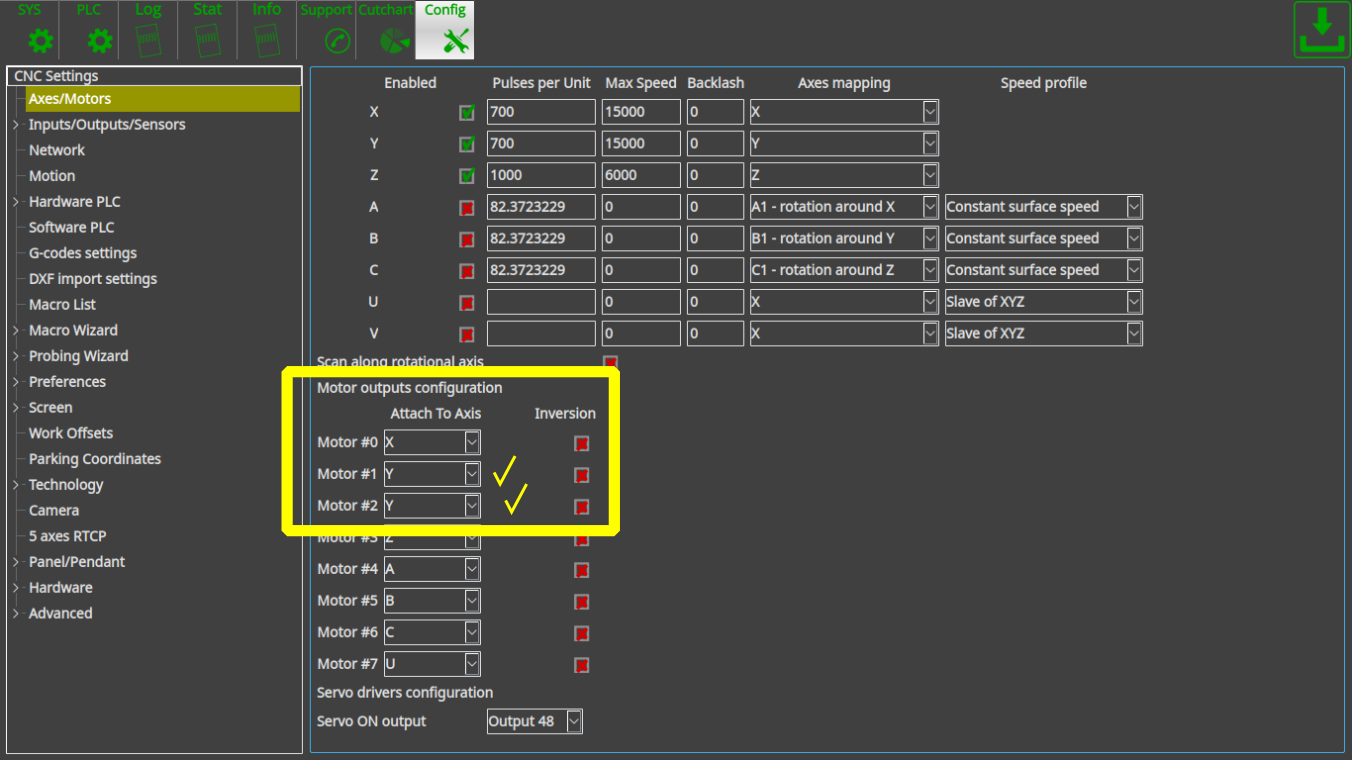

Axis pulse-dir signal can be connected/disconnected from Motor output by writing to CNC registers 0x70…0x75 (112…117)

- 0x70 (112) - Motor output #0

- 0x71 (113) - Motor output #1

- 0x72 (114) - Motor output #2

- 0x73 (115) - Motor output #3

- 0x74 (116) - Motor output #4

- 0x75 (117) - Motor output #5

Low 4 bits (0..3) of the writing value represent Axis to connect -

- 0 - X

- 1 - Y

- 2 - Z

- 3 - A

- 4 - B

- 5 - C

- 15 - disconnected

pulse-dir Direction will be changed (DIR signal inverted) if Bit #4 is set.

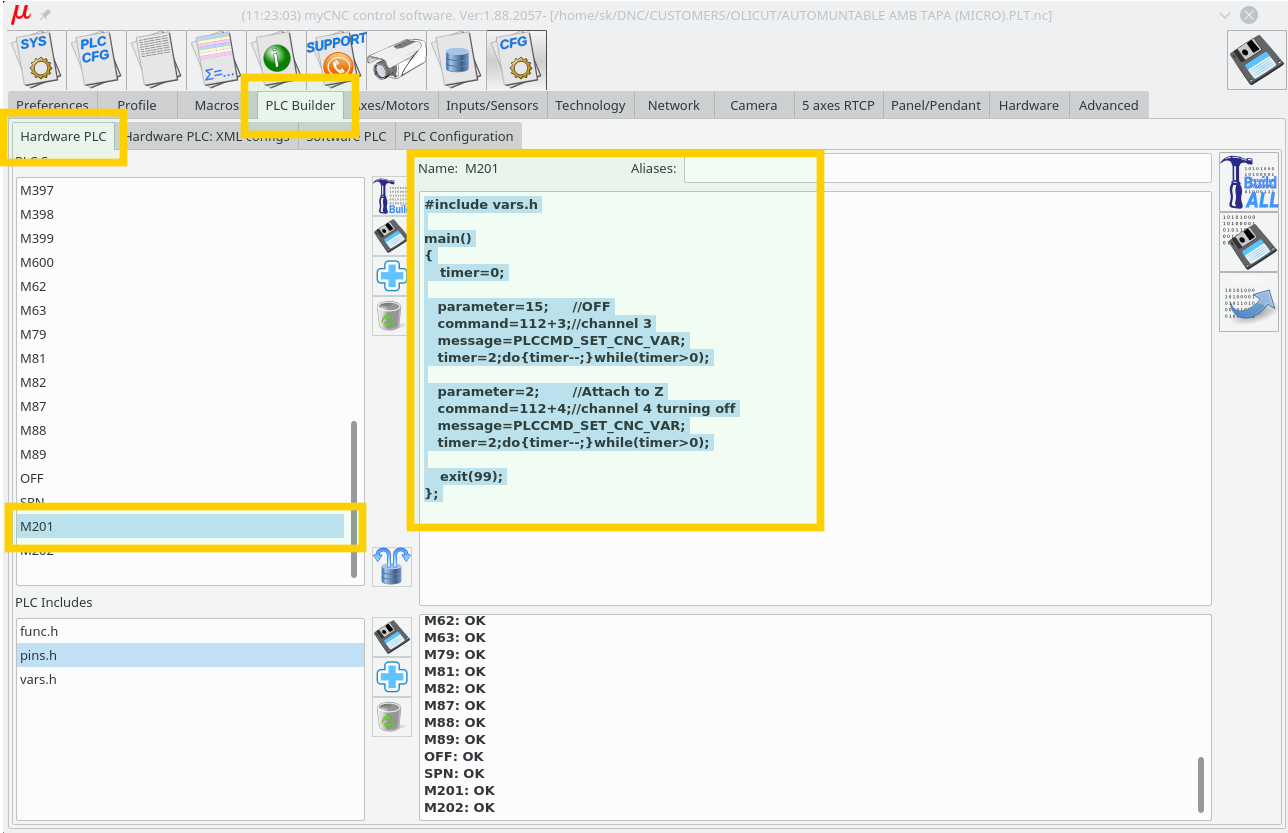

This way we add PLC procedures M201 and M202 to switch Z axis between Motor outputs #3 and #4

- M201.plc

#include vars.h main() { parameter=15; //OFF command=112+3; //channel 3 message=PLCCMD_SET_CNC_VAR; timer=2;do{timer--;}while(timer>0); parameter=2+16; //Attach to Z command=112+4; //channel 4 turning off message=PLCCMD_SET_CNC_VAR; timer=2;do{timer--;}while(timer>0); exit(99); };

- M202.plc

#include vars.h main() { parameter=15; //OFF command=112+4; //channel 4 message=PLCCMD_SET_CNC_VAR; timer=2;do{timer--;}while(timer>0); parameter=2+16; //Attach to Z command=112+3; //channel 3 message=PLCCMD_SET_CNC_VAR; timer=2;do{timer--;}while(timer>0); exit(99); };

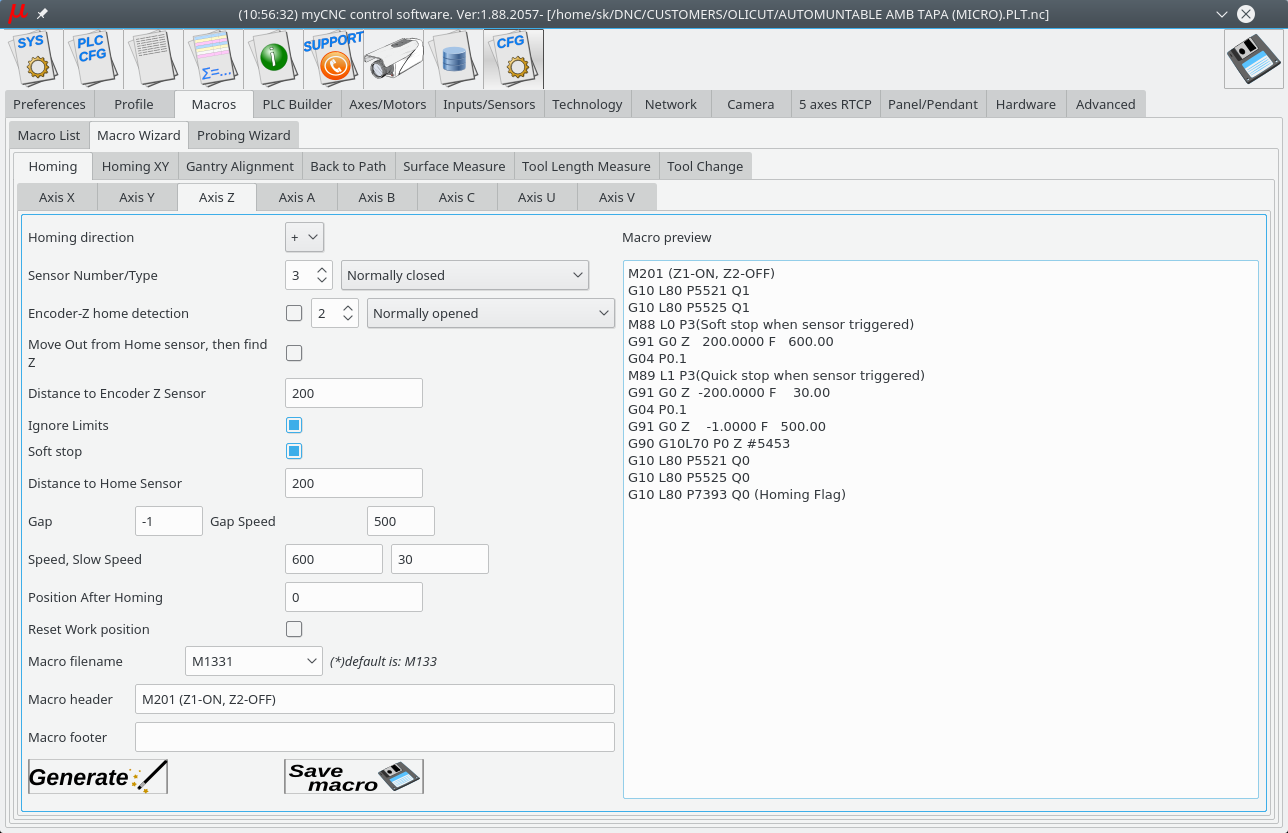

3. Homing for Z1, Z2 axes can be configured in Macro Wizard. M133 macro is usually used for Homing Z procedure. We will use macro names M1331 and M1332 for 2 homing procedures for every Z axis.

- M1331

M201 (Turn ON Z1 axis, OFF Z2 axis) G10 L80 P5521 Q1 G10 L80 P5525 Q1 M88 L0 P3(Soft stop when sensor triggered) G91 G0 Z 200.0000 F 600.00 G04 P0.1 M89 L1 P3(Quick stop when sensor triggered) G91 G0 Z -200.0000 F 30.00 G04 P0.1 G91 G0 Z 1.0000 F 500.00 G90 G10L70 P0 Z #5453 G10 L80 P5521 Q0 G10 L80 P5525 Q0 G10 L80 P7393 Q0 (Homing Flag)

- M1332

M202 (Turn OFF Z1 axis, ON Z2 axis) G10 L80 P5521 Q1 G10 L80 P5525 Q1 M88 L0 P4(Soft stop when sensor triggered) G91 G0 Z 200.0000 F 600.00 G04 P0.1 M89 L1 P4(Quick stop when sensor triggered) G91 G0 Z -200.0000 F 30.00 G04 P0.1 G91 G0 Z 1.0000 F 500.00 G90 G10L70 P0 Z #5453 G10 L80 P5521 Q0 G10 L80 P5525 Q0 G10 L80 P7393 Q0 (Homing Flag)

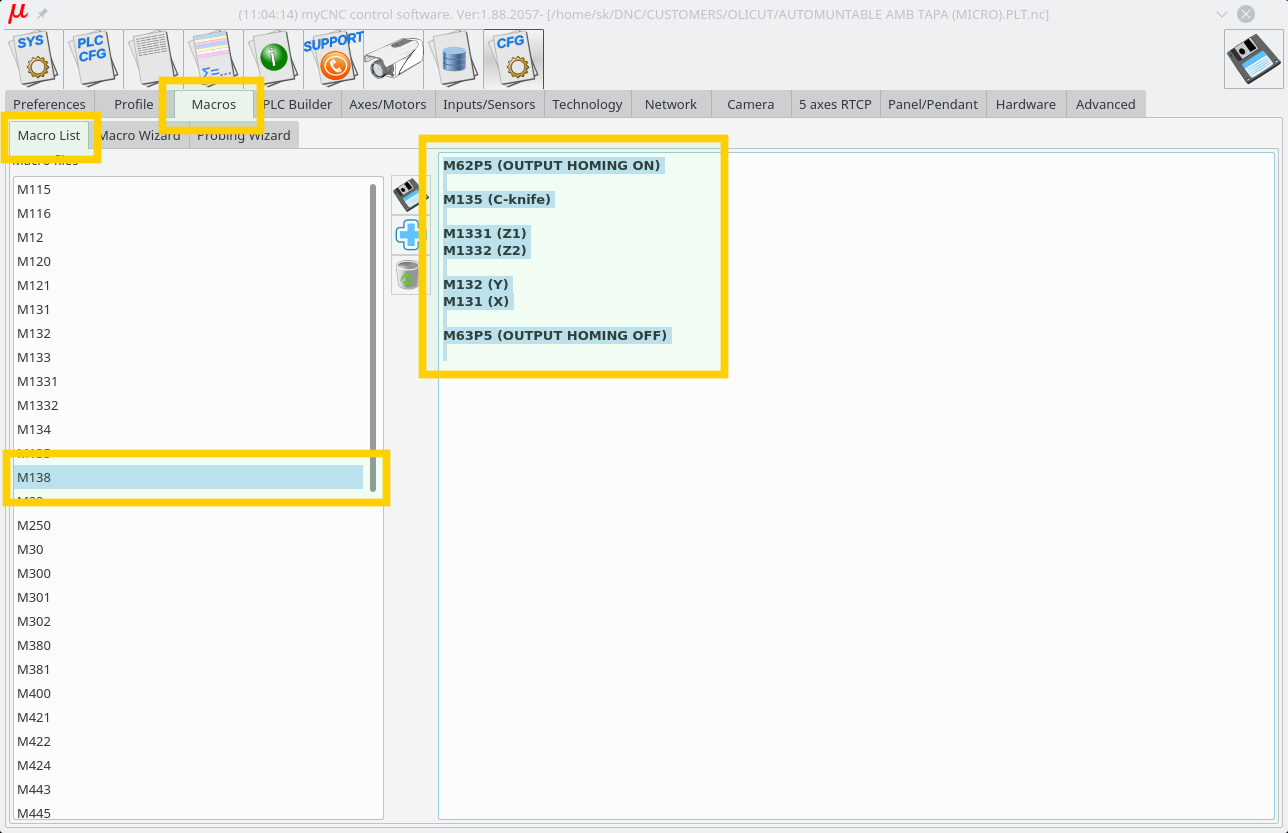

4. M138 macro is used for Home-All procedure. It should be fixed to support Z1, Z2, tangential knife homing and OUTPUT_HOMING output described in “pins.h”

- M138

M62P5 (OUTPUT HOMING ON) M135 (C-knife) M1331 (Z1) M1332 (Z2) M132 (Y) M131 (X) M63P5 (OUTPUT HOMING OFF)

5. M6 - Tool Change macro for multitool configuration.

- M6

M600 P#5409 if [ #5409 NE 1 ] 100 M150 GOTO 1000 N100 if [ #5409 NE 2 ] 200 M151 JUMP 1000 N200 if [ #5409 EQ 3 ] 300 G10 L80 P7005 Q0 JUMP 1000 N50 G10 L80 P7005 Q1 N300 N1000 G10 L81 P5400 Q5409 (set current tool number)