This is an old revision of the document!

Table of Contents

Torch Height Control (THC)

ARTICLE CURRENTLY UNDER CONSTRUCTION

THC checkup

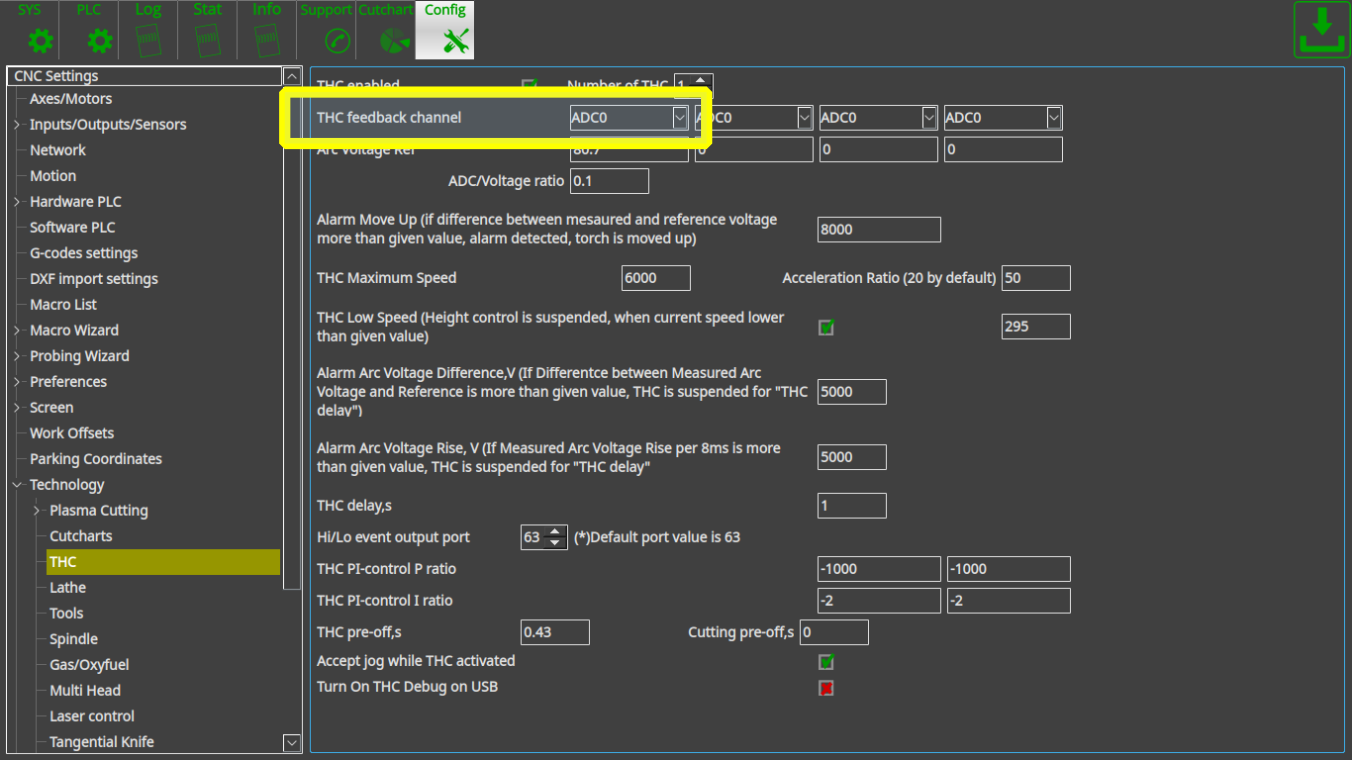

Check the ADC channel number

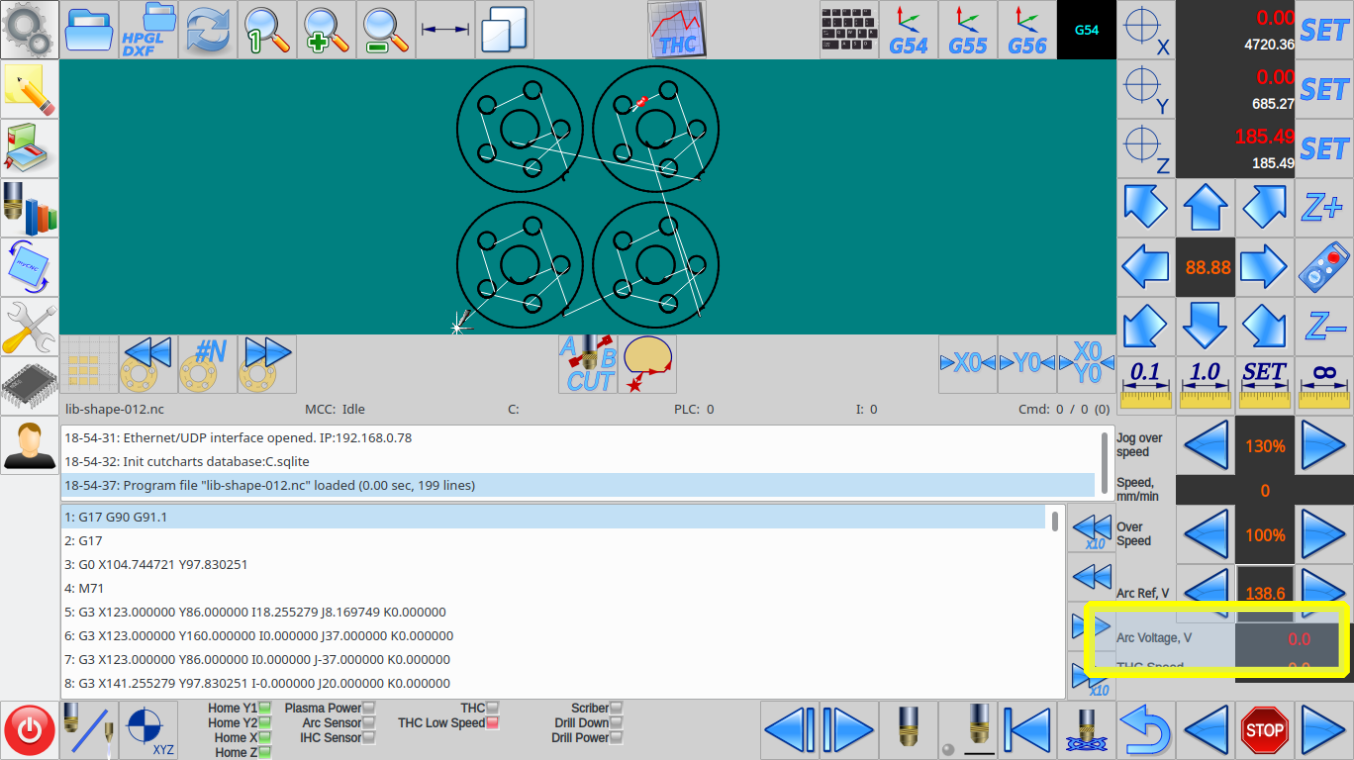

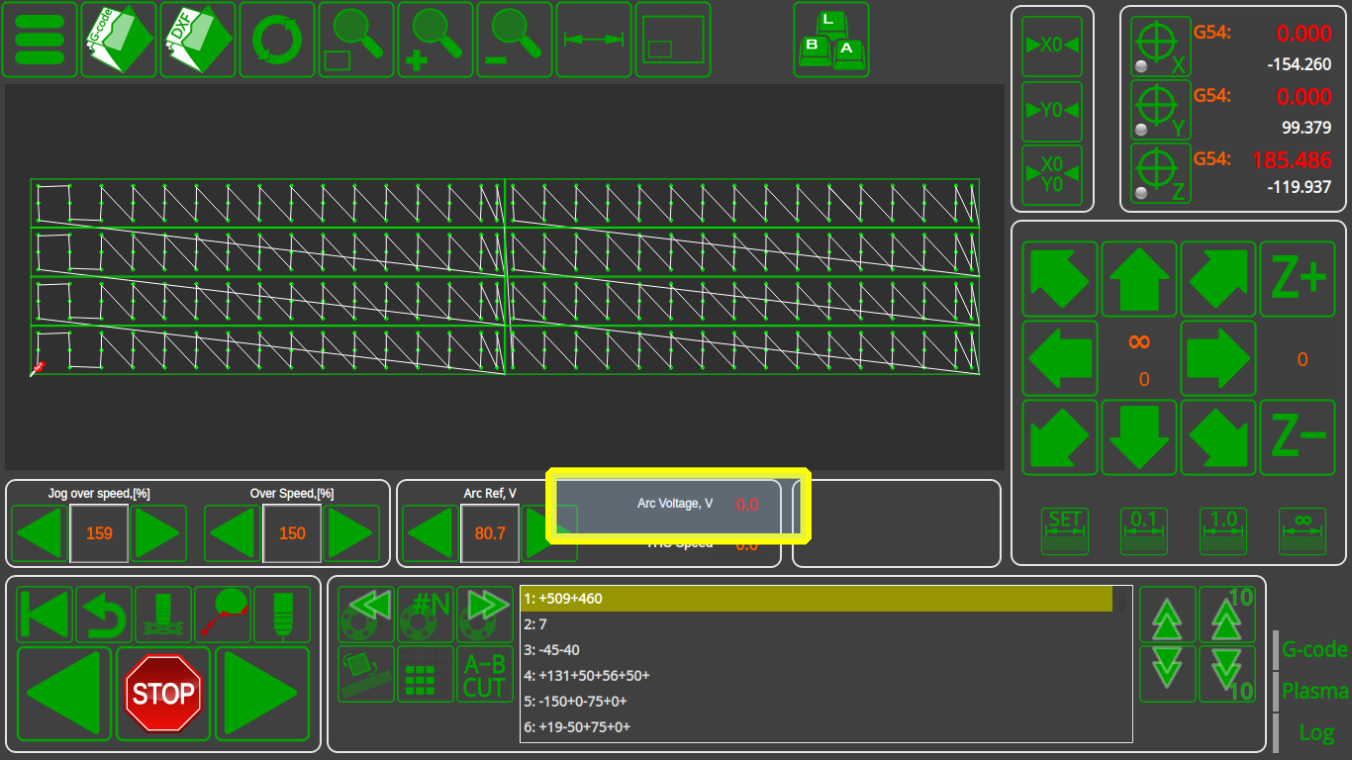

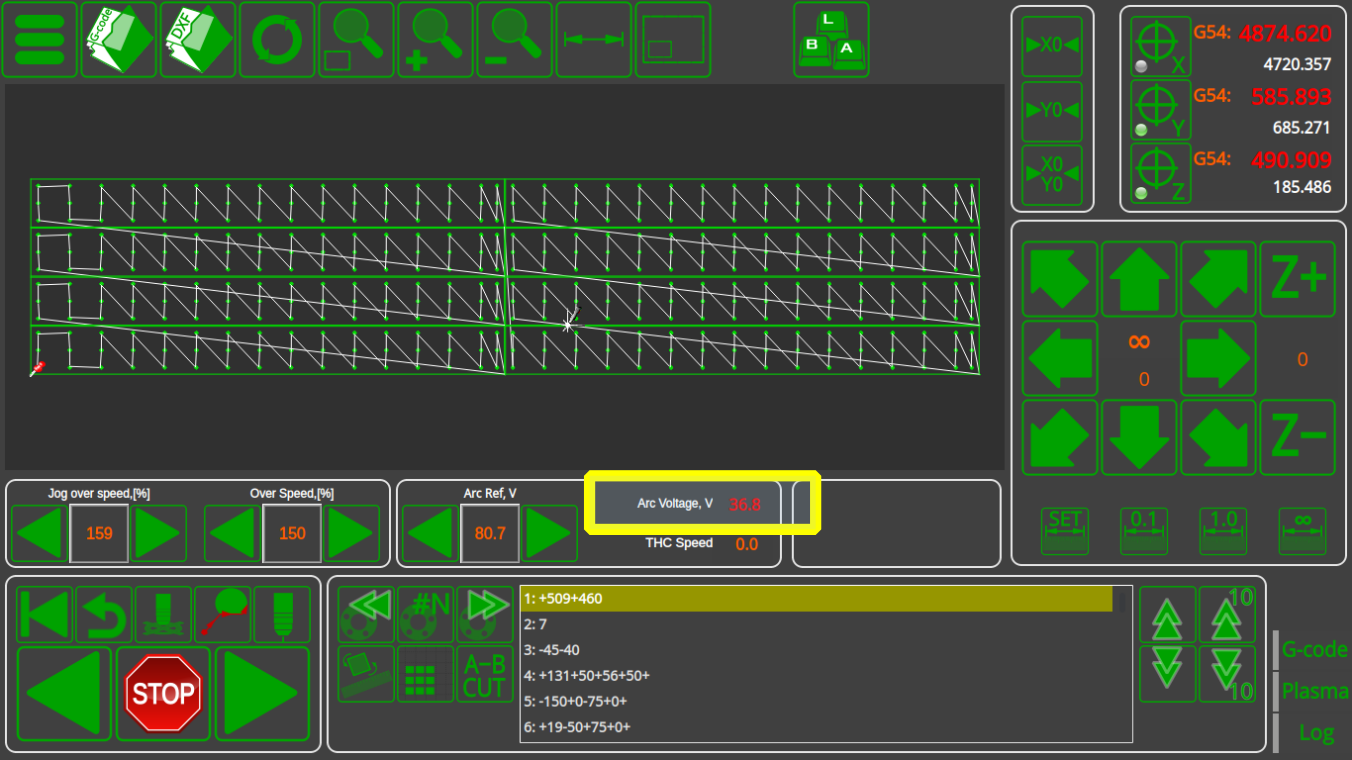

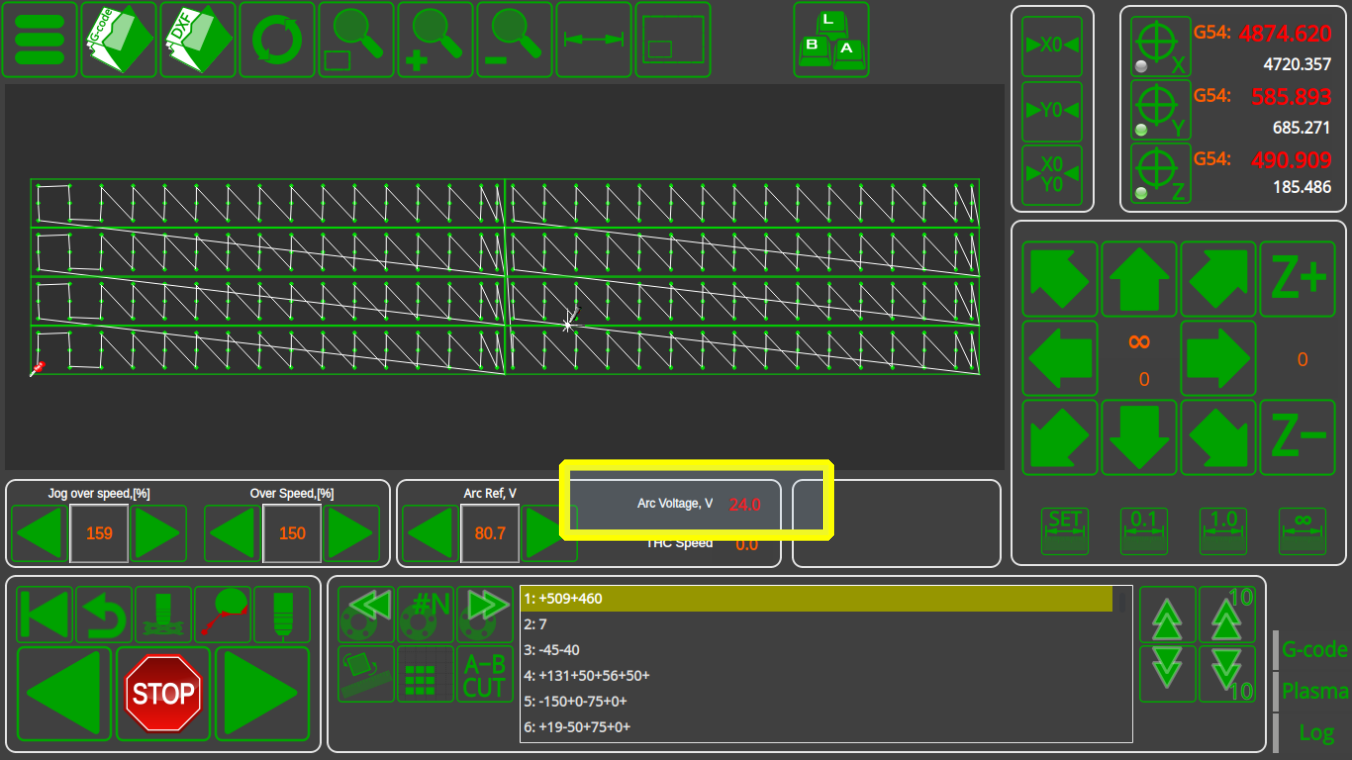

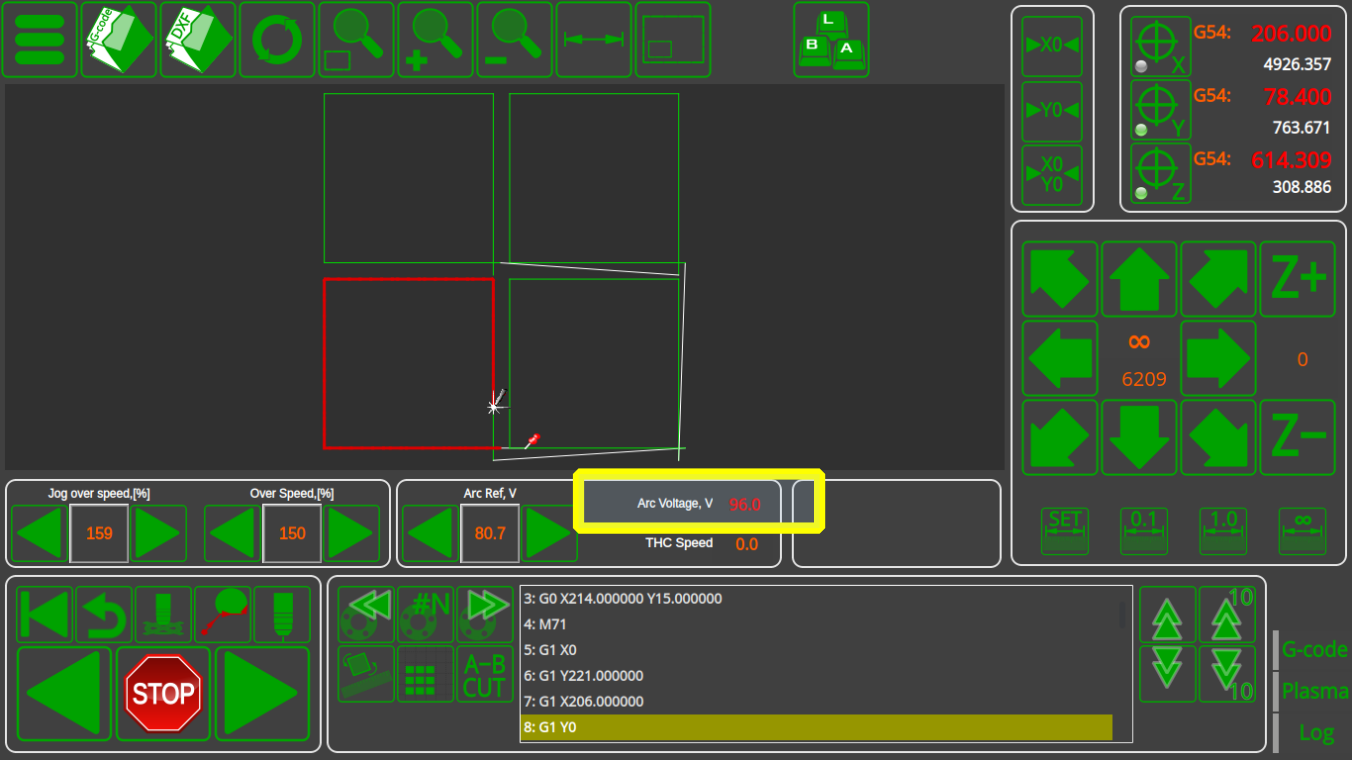

Arc Voltage measured value is displayed on the myCNC main screen. Arc voltage signal should be connected to the proper ADC input number. This number can be set up in the THC configuration dialog.

Connect the test signal (for example 24V from test power source) to the THC ADC input and check the voltage value displayed. Test signal should be connected through the Arc Voltage Divider you use (not directly to the board's ADC input).

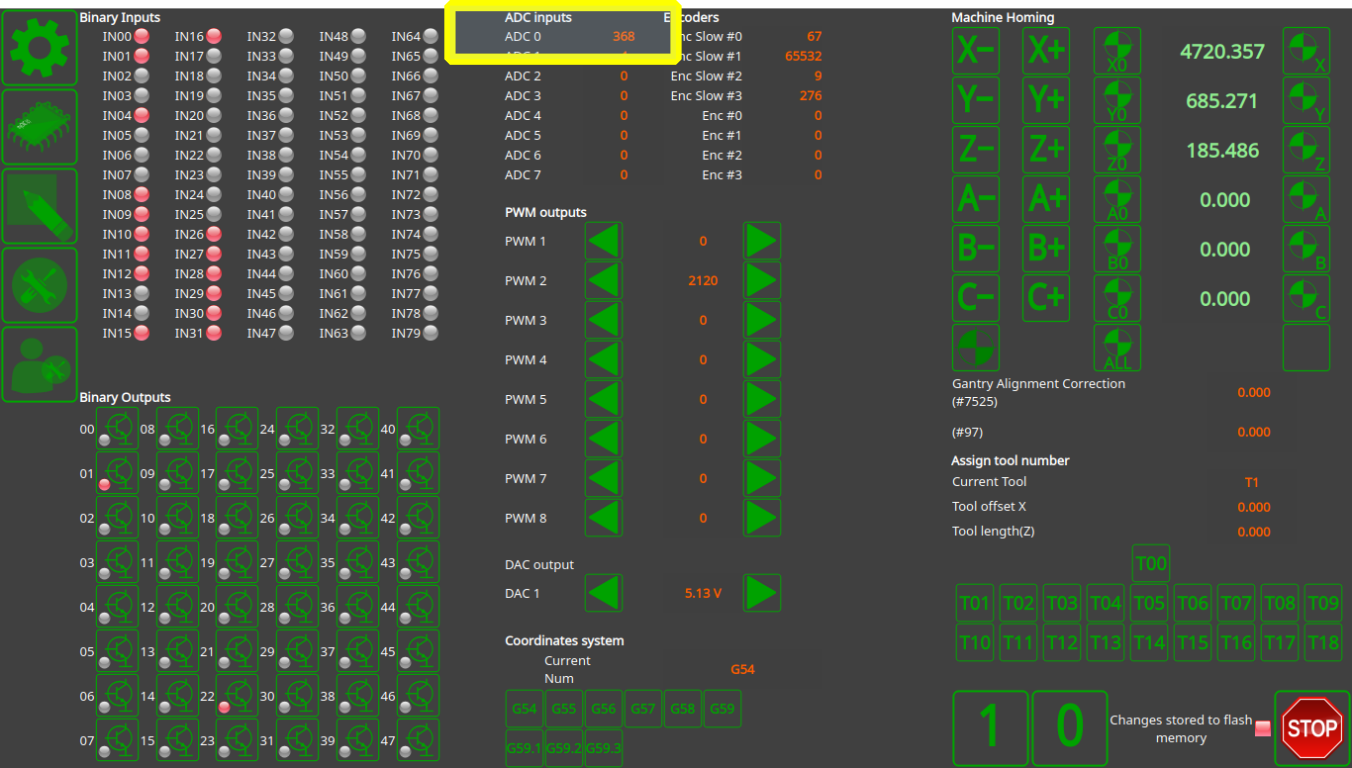

If you don't see any voltage on the display, then:

- go to the “Diagnose” widget,

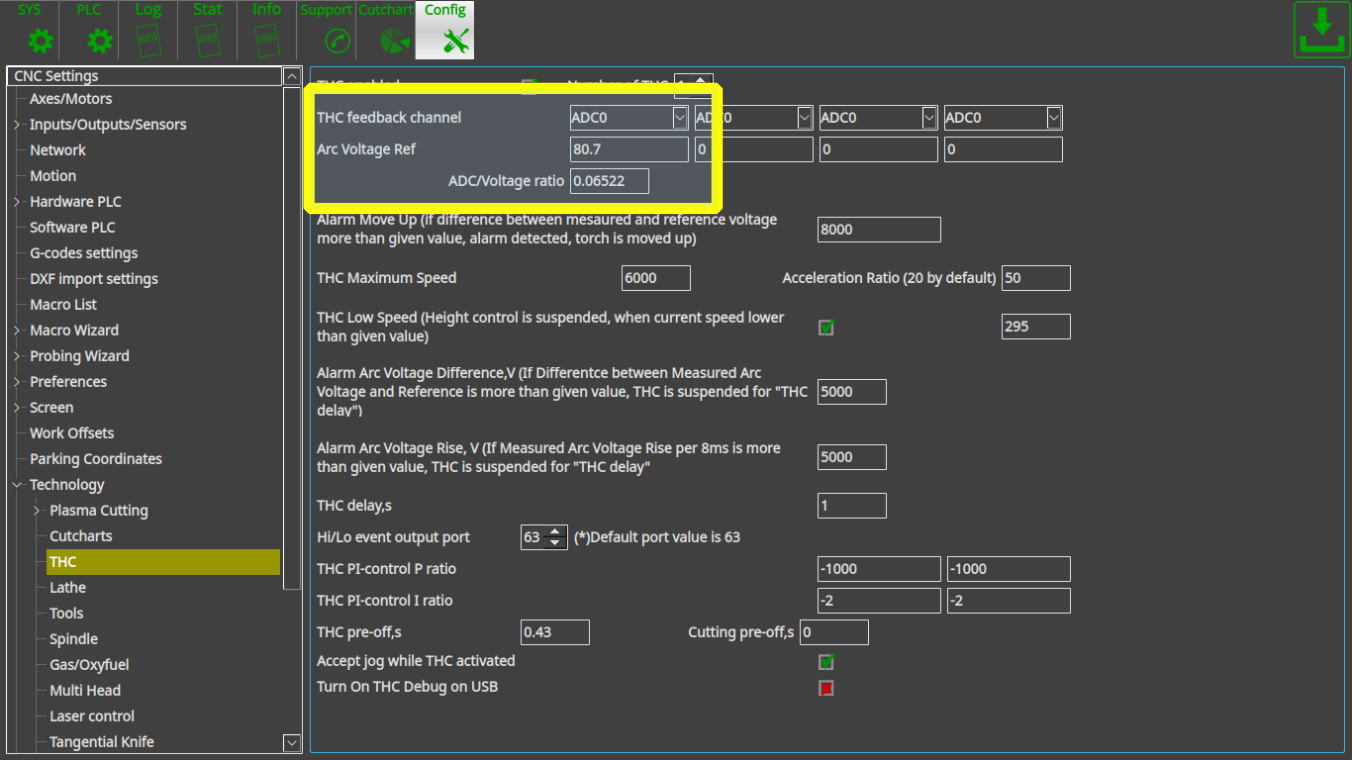

- go to the THC settings widget again and fix the “ADC/Voltage” ratio. The value should adjusted to

K1=24/36.8=0.6522

Current ratio is “0.1” (on the screen above), so total ratio would beK=0.1*24/36.8=0.06522

Check THC/PID settings

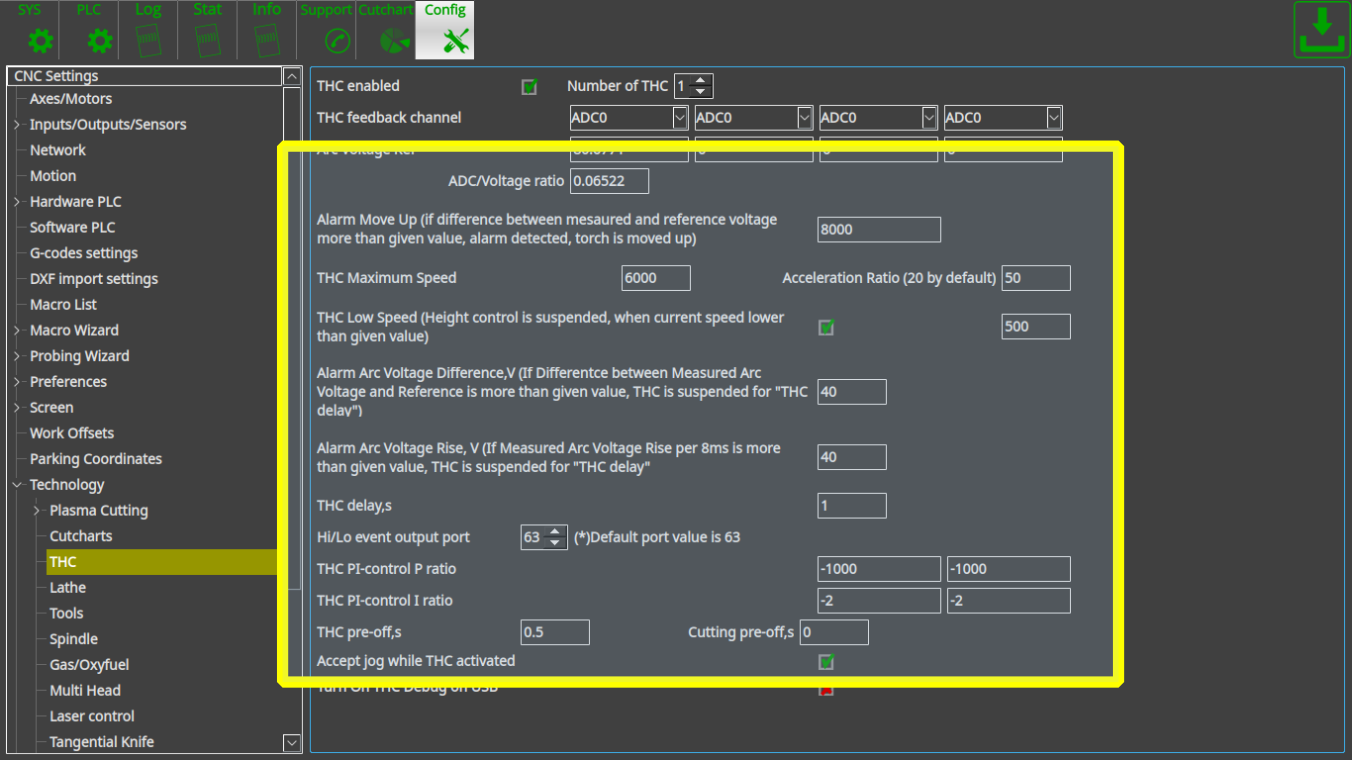

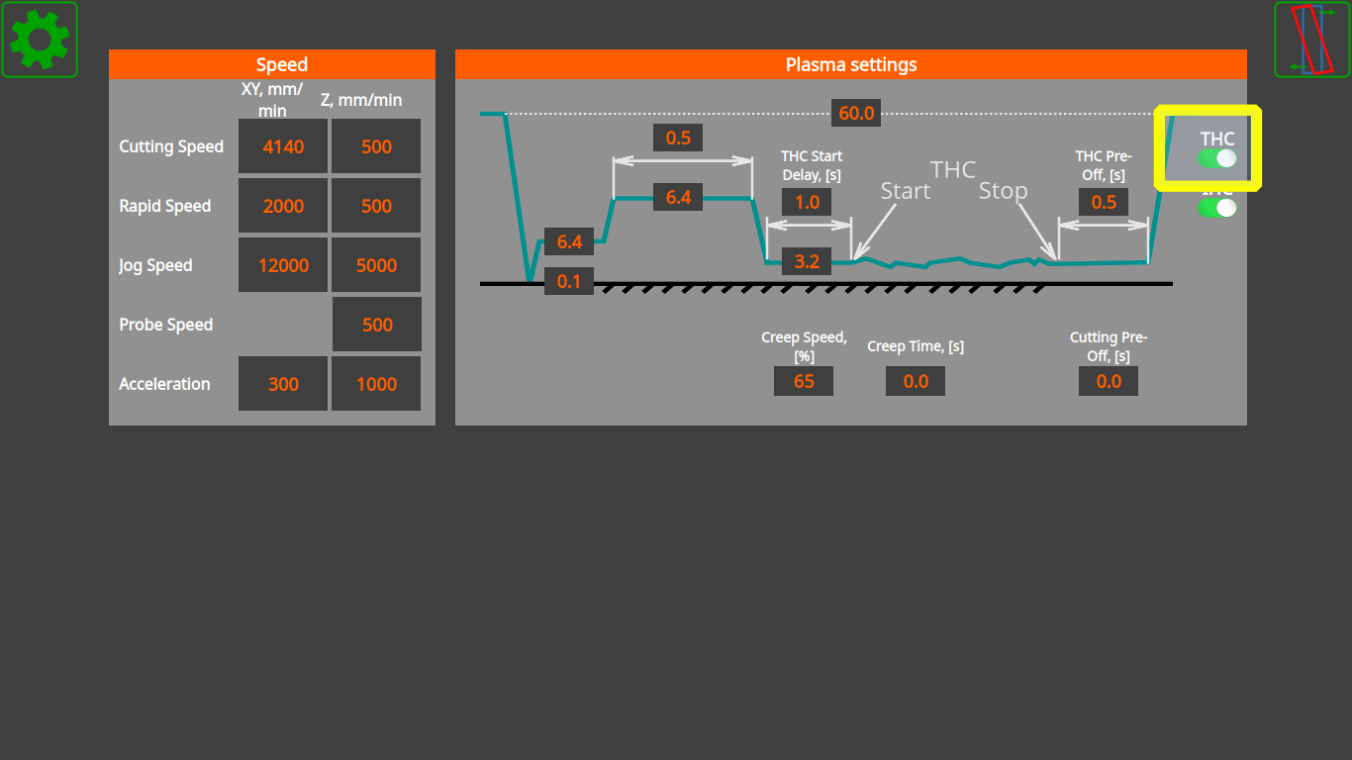

Now it's a good time to check and edit the default THC/PID settings

The screenshot above illustrates the default values only. “Recommended” values depend on machine speed, sheet thickness, plasma power source and torch type, and vary from user to user. In this manual, values that are suitable for one particular configuration will be shown.

In order to set up THC properly, follow the instructions below:

1. Select the green check mark in the THC Enabled field.

2. Select the number of THC you have in your setup (usually 1)

3. Select the feedback channel as described in the procedure above.

4. Select your reference voltage. This can be done in two ways - either by using a value from literature (by going to the

"Alarm Arc Voltage difference..." and "Alarm Arc Voltage Rise" settings help to prevent the torch diving while moving through the cut, on low speed corners etc. However, if the reference voltage is very different from the real measured voltage (more than these values), Height control may not start at all. You may want to temporarily set these values to "1000" to disable this feature and test the THC.

THC PI-control ratios may vary depends on a sheet thickness and plasma power source type. The higher the P-ratios absolute values, the higher the Height Control Speed. According to our experience, I-ratios should be set to "-2...-6". Higher I-ratio values may lead to oscillation during height control. Both P- and I-ratios should be NEGATIVE for Arc Voltage Height Control. This means - The higher Arc Voltage (if compare with reference position), The Lower should be Position.

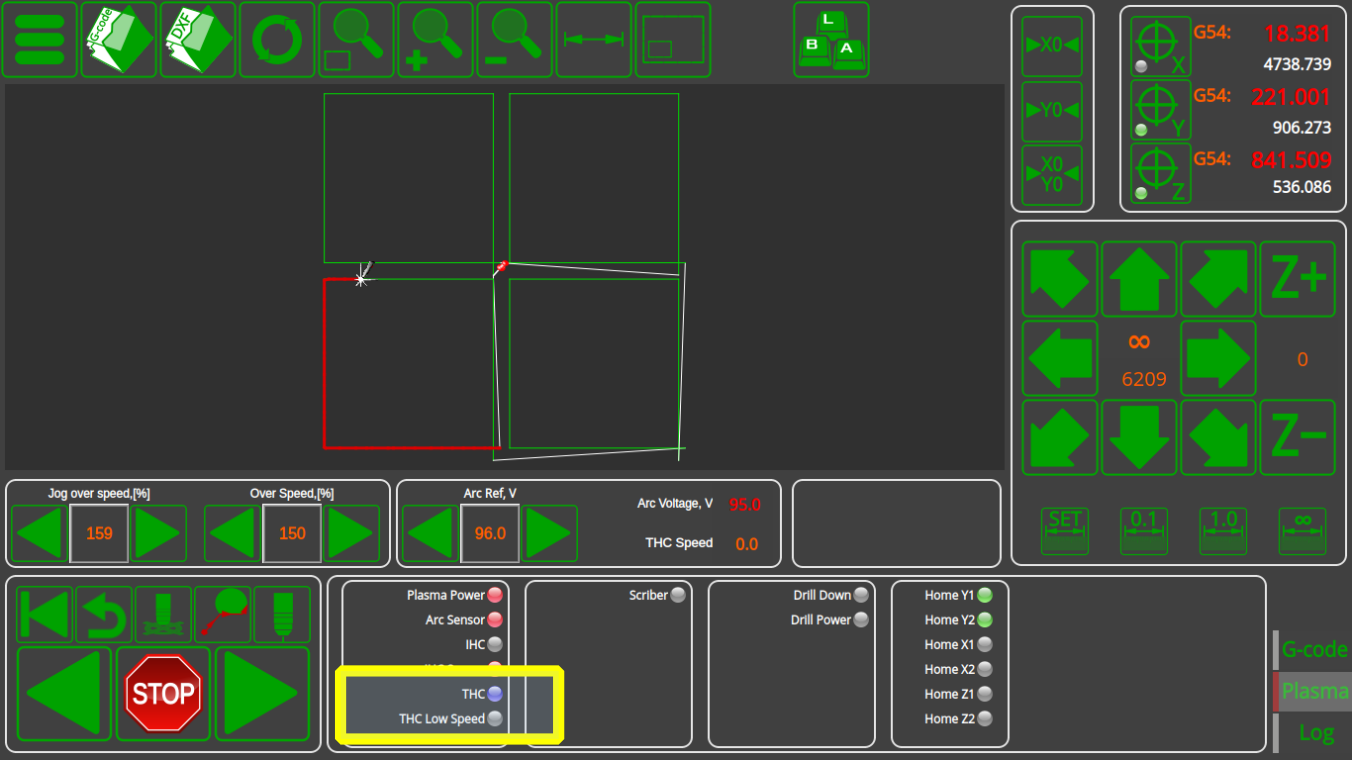

Check THC is ON

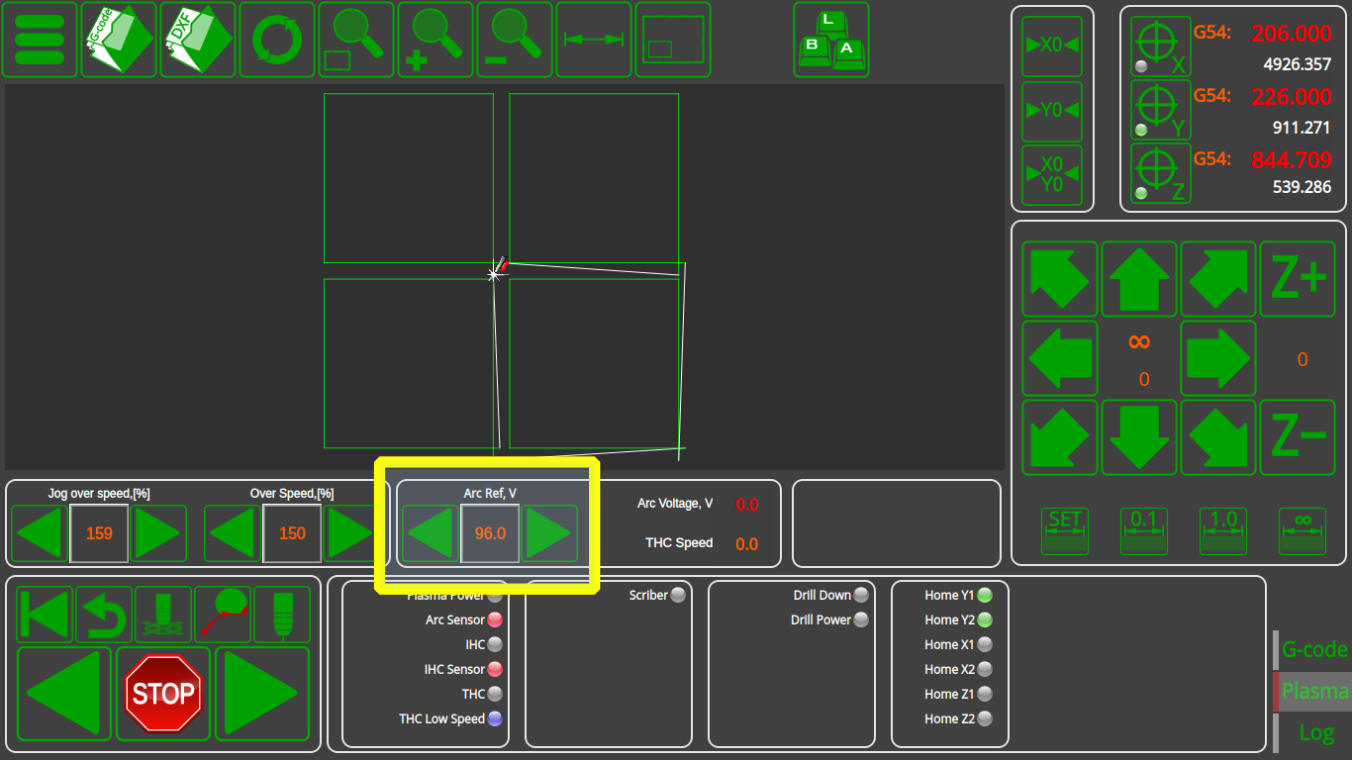

The next step is to check if THC is ON in user settings.

It can be a button in User settings of an item in PLC settings. Both settings actually are the same and represent the same variables.

Find a good Reference Voltage value

If you don't have a recommended Reference Arc Voltage value tables from power source manufacturer (Cur Charts), you may need to find a good reference arc voltage value. To find it

- Disable THC & IHC

- Set desired height from the sheet

Set the reference voltage value

Check THC working

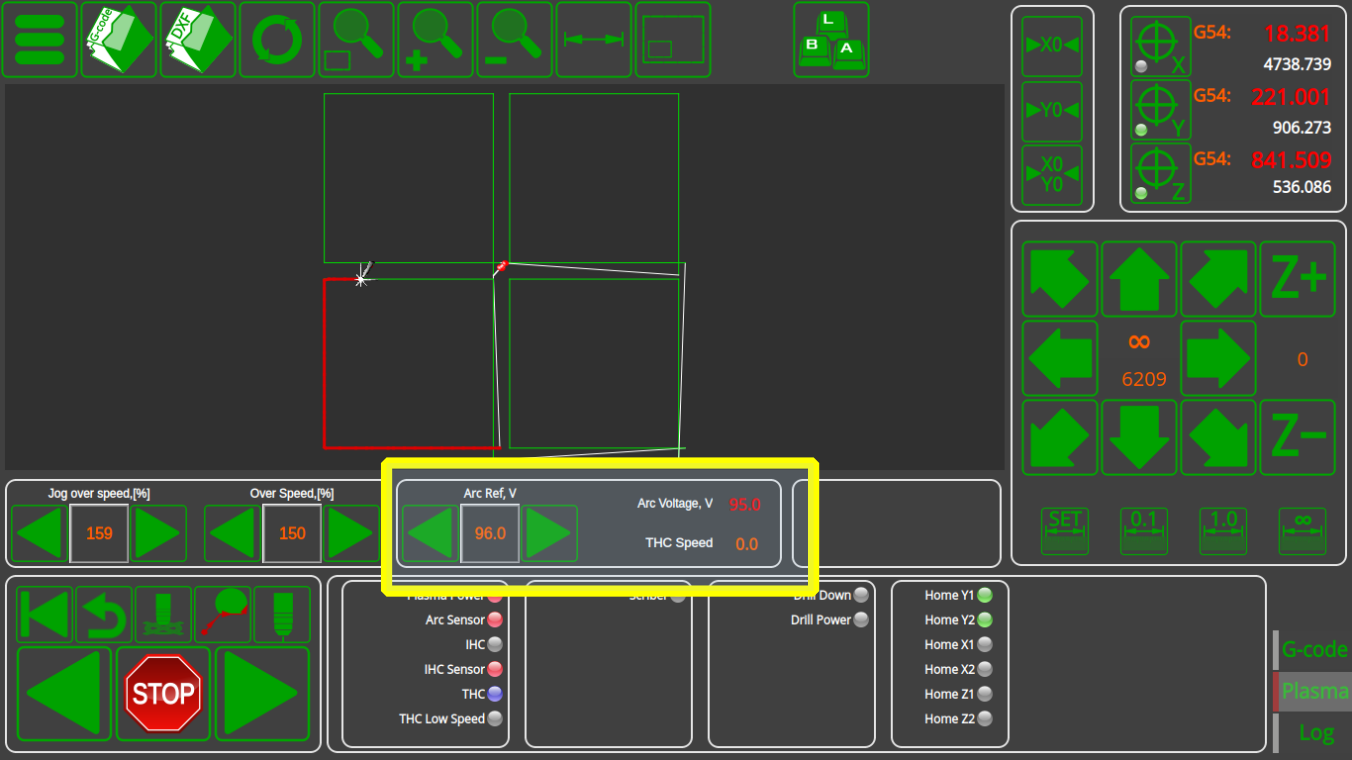

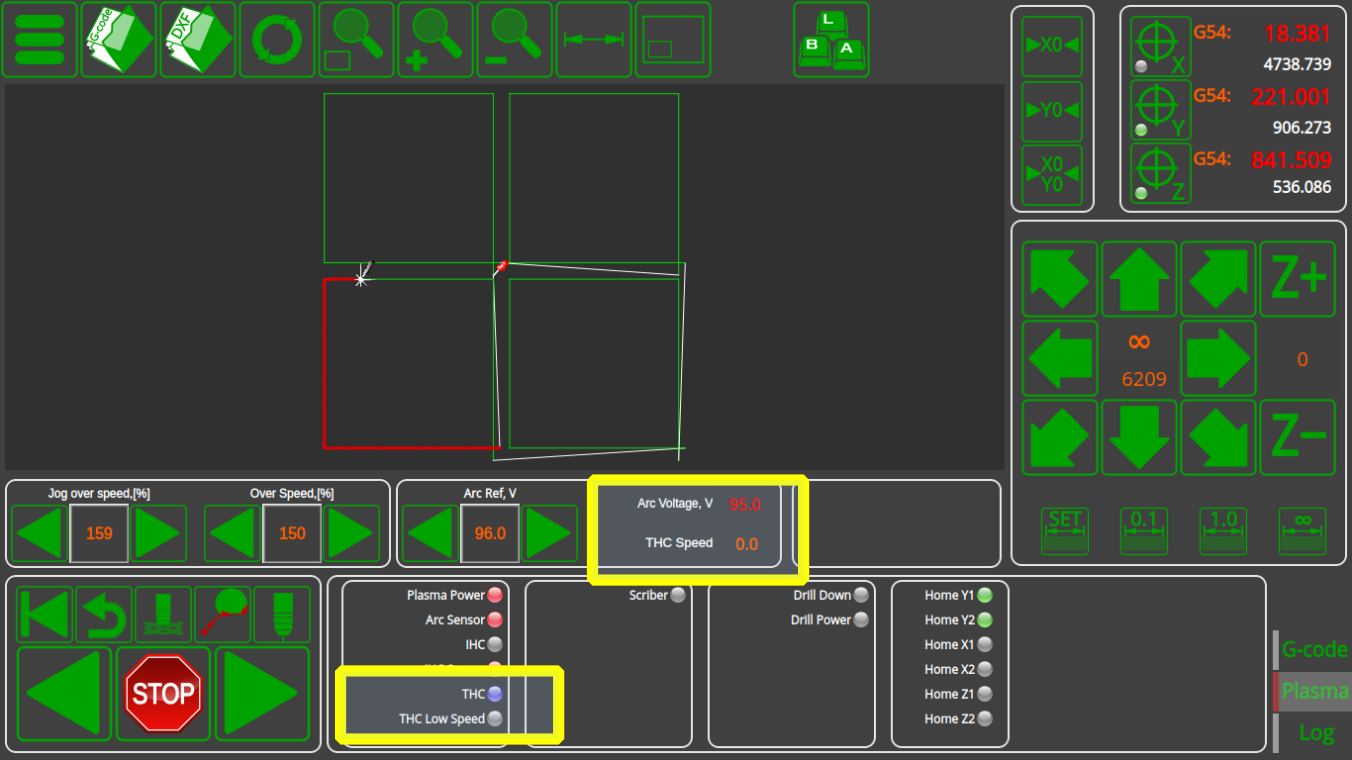

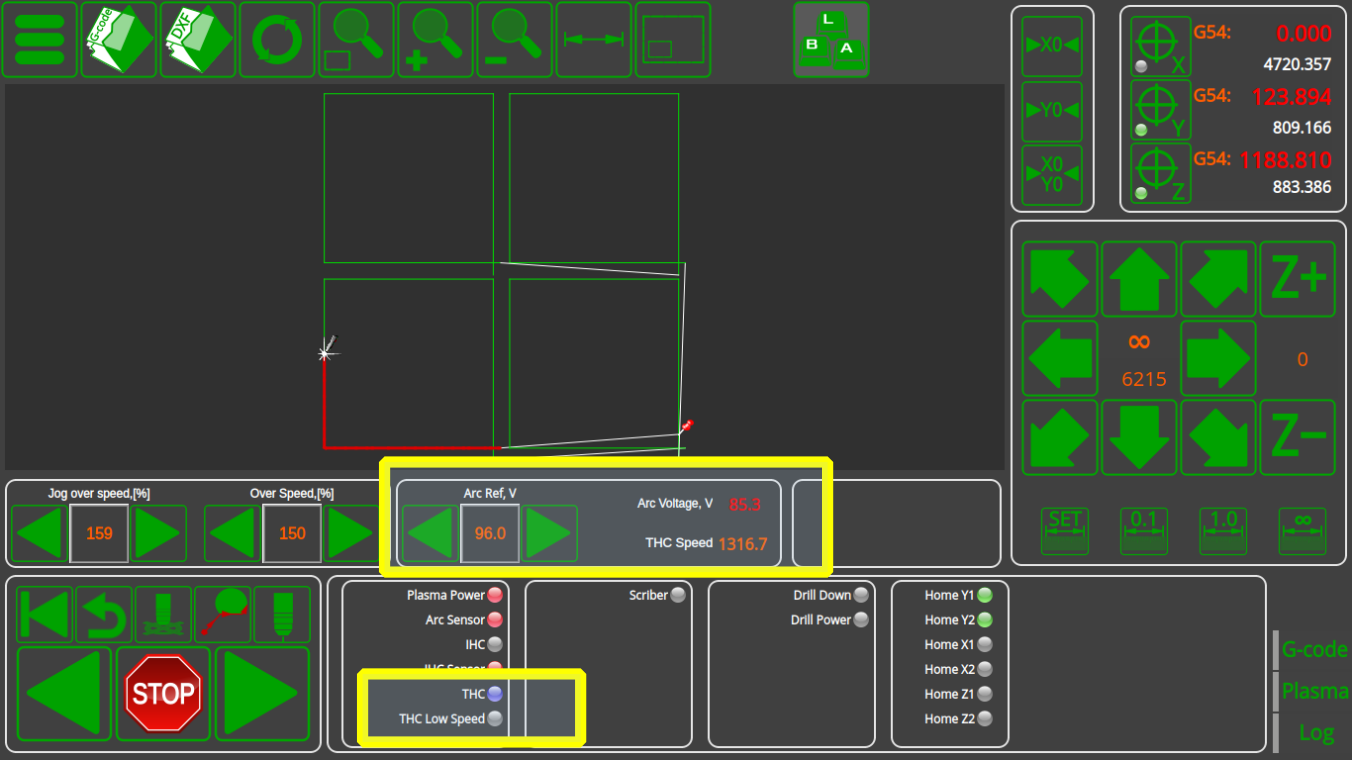

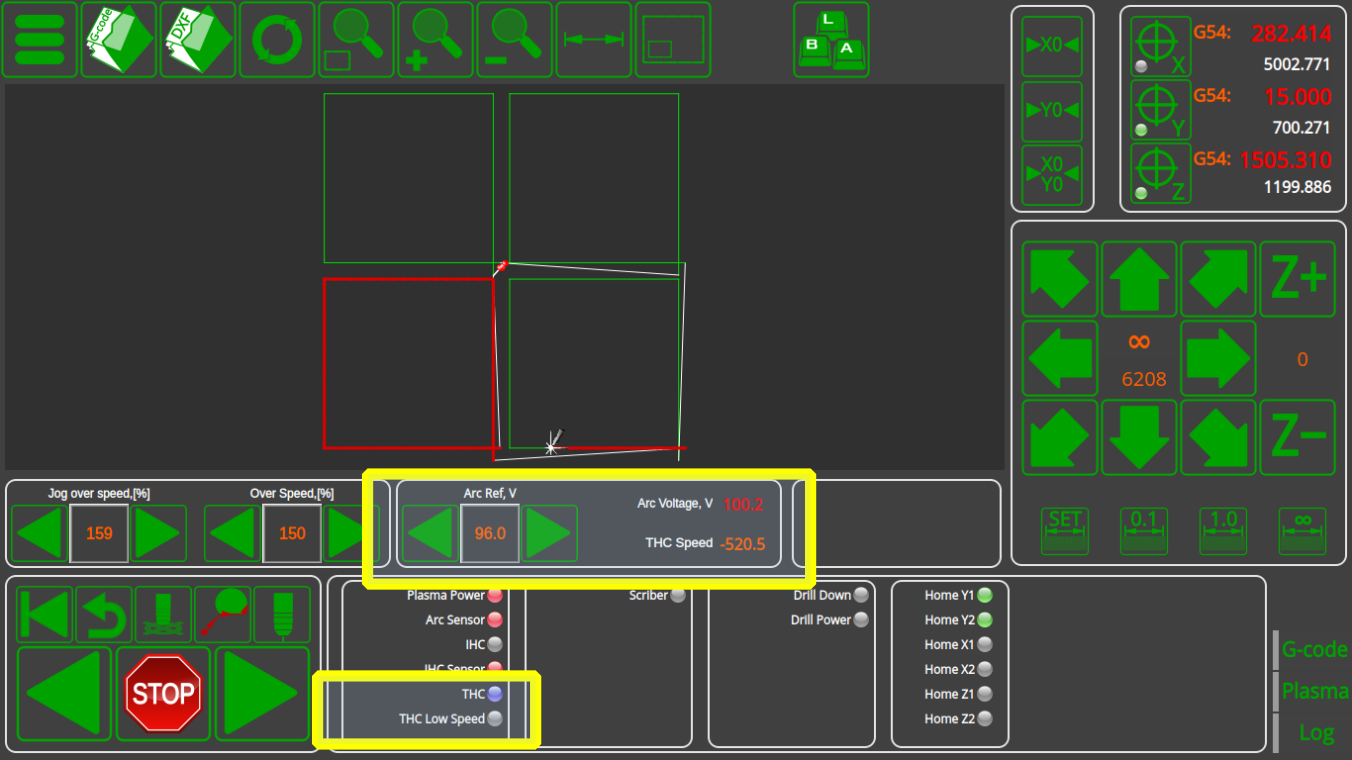

Turn On back the THC in User settings and make test cutting.

- “THC Speed” display should show the current Height Control Speed. The current implementation takes the display speed to be in internal machine units, so the absolute “THC Speed” value might not correspond to the actual physical speed of the machine. However, this is still useful since you can see the following:

Registers to control THC

| Variable Name | Value | Comments |

|---|---|---|

| THC #0 | ||

| GVAR_THC0_ARC_VOLTAGE_REF | 7011 | Arc Voltage Reference value. This register is written while Load Cutcharts. It can be updated automatically if THC is activated in “Measure” mode. In this case, after THC activated and given “THC delay” controller measures real Arc Voltage, save this value as “Arc Reference” and keeps this value during the cut. Rotary encoder can be connected to this register to implement on-the-fly Arc Voltage adjustment |

| GVAR_THC0_ARC_VOLTAGE_ADJ | 7012 | Adjustment Value for Reference Arc. Either potentiometer or rotary encoder can be connected to this register to be able to adjust Arc Voltage reference on the fly VolategArc Voltage Reference value. |

| GVAR_THC0_ARC_VOLTAGE_REF2 | 7013 | Register contains sum of Arc Voltage Reference register (#7011) and Adjustment register (#7012). The software automatically updates register value if any of register 7011,7012 is changed. The register is available for reading to display adjusted Arc Voltage reference value |