This is an old revision of the document!

Table of Contents

MyCNC closed loop configuration

Servo ON handling

There are few ways to Enable/Disable Servo PID loops in myCNC software

1. On-Screen button. To enable/disable Servo PID control button should have actions:

action="servo-pid-on" (enable pid) action="servo-pid-off" (disable pid)

For example

Buttons for Servo-ON and Servo-OFF

<gitem where="toolbar-servo" image="motor/motor-start" action="servo-pid-on" height="80" event="pressed-delay-1000" type="button"/> <gitem where="toolbar-servo" image="motor/motor-stop" action="servo-pid-off" height="80" type="button"/>

Popup widget container for Servo Pid On/Off buttons

<quick-popup-layout> <current>popup-servo</current> <layout stretch="0" name="popup-servo" wa="80;160;right" orientation="vertical" skin="skin/metal-01"> <widget stretch="1" spacing="0" name="toolbar-servo" orientation="vertical">myitems</widget> </layout> </quick-popup-layout>

Button to show containner with 2 buttons for servo-on/servo-off buttons and led to show current servo pid state

<gitem where="magic" position="960;0" width="80" height="80" image="motor/servo-driver" action="mypopup-toggle:popup-servo" xattr="56;4;20;20;led;green;round" address="outputs" number="47" type="xbutton" />

2. Using Global Variables API. Global variables 60000 and 60001 are mapped to turning On and Off Servo PID control.

- Write “1” to register number 60000 will turn ON Motor closed-loop control PIDs

- Write “1” to register number 60001 will turn OFF Motor closed-loop control PIDs

3. Automatic Servo ON/OFF. There are 2 handler procedures in Software PLC can be used to automatic PID ON/OFF.

- _HANDLER_INIT - procedure executed once judt after CNC control software loaded, connection with myCNC controller established and a complete configuration is sent to the controller.

- _HANDLER_EXIT - procedure executed while myCNC control software shut down process.

To handle automatic Servo ON/OFF writing to registers 60000, 60001 should be added to handler procedures. Example are below

- __HANDLER_INIT.PLC

main() { gvarset(60000,1); //turn Servo PIDs On exit(99); };

- __HANDLER_EXIT.PLC

main() { gvarset(60001,1); //turn Servo PIDs Off exit(99); };

Analogue -10V..+10V/Incremental encoder closed-loop setup

Pulse-Dir/Incremental Encoder closed-loop setup

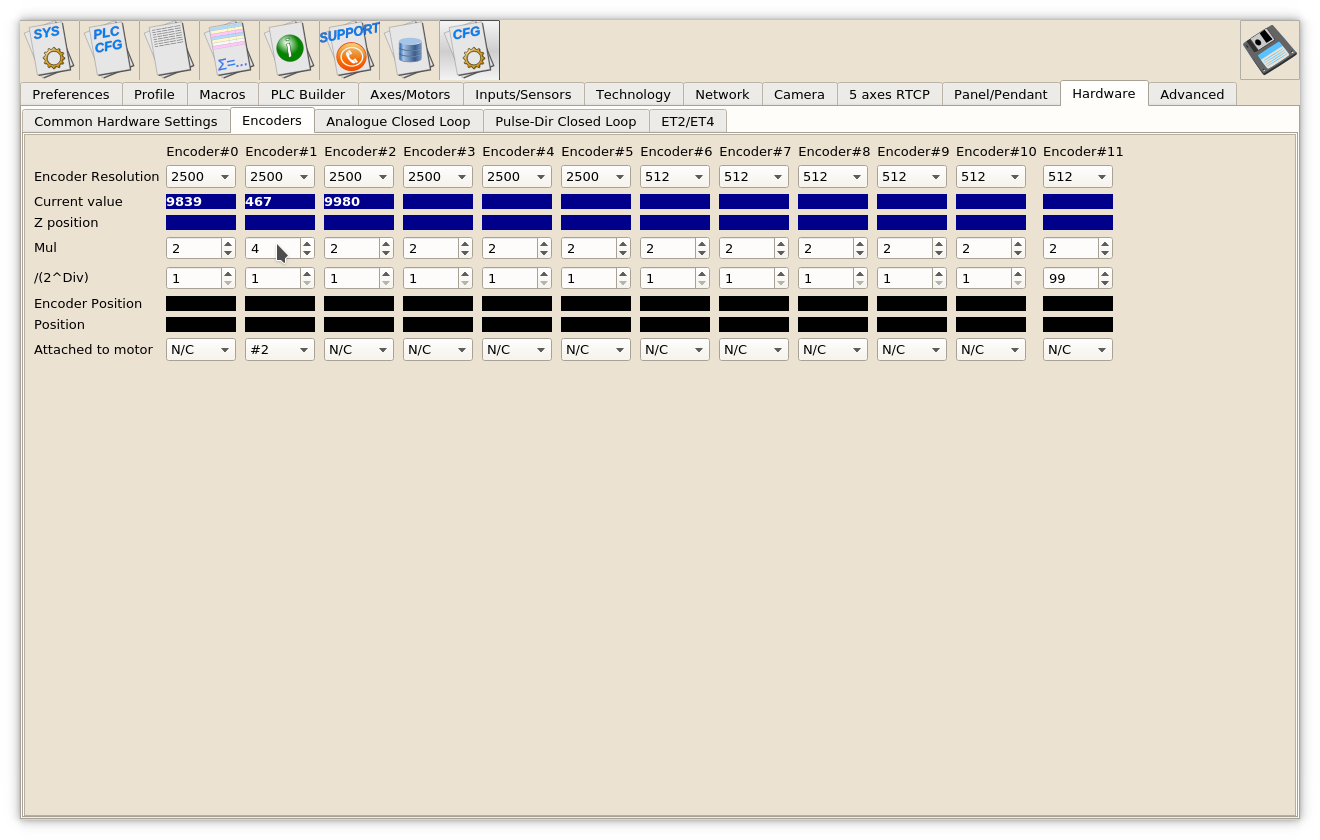

Let's use Motor output #2 (configured as axis X) and Encoder #1 to build closed-loop PID control.

- Set Mul and /(2^Div) ratios to get result Encoder resolution equal to Pulses-per-Unit resolution. For example

Servo driver with 2500 pulses per revolution, Electronic gears "1" and ball screw 5mm are used. Linear encoder with 1um resolution used as a feedback. Pulses per unit are (2500*4)/5=2000 pulses per mm Original Linear encoder resolution (1um) is 1000 pulses per mm, need to set multiplier to "4" and divider to "1" to get result ratio 4/(2^1)=4/2=2 and result Encoder resolution - 1000* 4/(2^1)=2000

- Set Attached to motor to “#2”

- Goto Pulse-Dir Closed Loop ang setup PID parameters for PID attached to Motor#2. The most importalt parameters are

- PID proportional ratio Kp

- PID integral ratio Ki

- PID integral limit. Integral value will be limited by given value.

- Encoder channel used as PID feedback