Table of Contents

Server API

This article serves as the main reference point for all myCNC material related to the myCNC Server API.

The server API allows to control movement and machine coordinates remotely, via a series of commands.

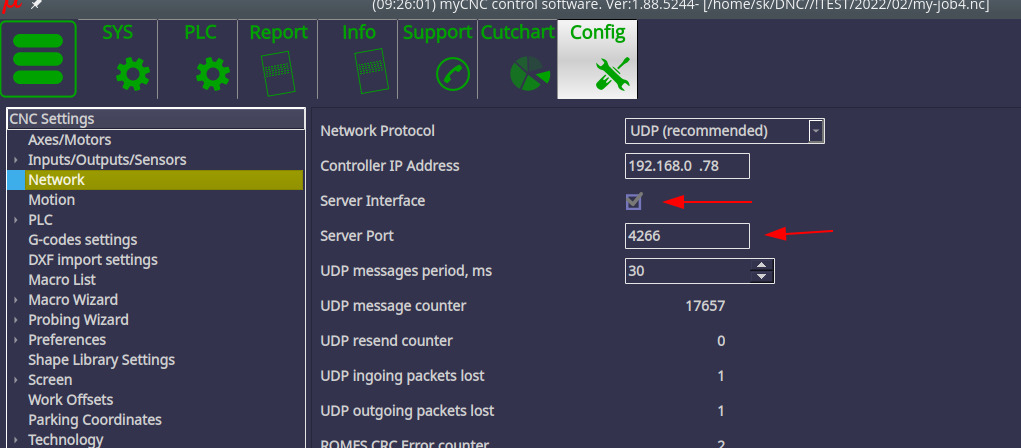

To enable Server API functionality, first head into your Settings > Config > Network, and enable the Server Interface option, as well as set a Server Port (the server port will be used to connect to your system via the telnet command, for example telnet 127.0.0.1 4266):

A list of Server API commands is presented below for jog control, etc. To obtain a full list of commands, type ? while connected to the remote host:

A full list of commands is provided below:

| Parameter | Description |

|---|---|

| EchoMode | |

| ProgramFileOpen | |

| ProgramBegin | |

| ProgramAppend | |

| ProgrmaEnd | |

| ProgramPlay | Starts running the program |

| ProgramPlayBack | |

| ProgramPlayStep | |

| ProgramPlayStepBack | |

| ProgramPause | |

| ProgramStop | Stops the running program |

| ProgramReset | Resets the program to the beginning |

| GetEstimateTime | |

| GetMachinePosition | Returns all of the current machine position coordinates |

| GetProcess | |

| GetWorkPosition | Returns all of the current work (program) coordinates |

| GetMyCNCVersion | |

| GetFVariable | Returns the value stored in a global variable (as double) |

| GetIVariable | Returns the value stored in a global variable (as int) |

| GetReady | |

| LineAppend | |

| GetScanData | |

| GetSensors | |

| GetMCC | Get Motion Control Code - read machine status, returns a number (for example, 3) |

| GetMCPtr | Get Motion Control Pointers |

| GetHW | |

| GetHWDAC | |

| GetHWADC | |

| GetHWInputBit | Returns (reads) the state of a particular input |

| GetHWInputs | Returns (reads) the state of an input group |

| GetHWOutputs | |

| GetHWPWM | |

| GetPWMs | |

| GetPausedLine | |

| GetLastMessage | |

| GetWorkState | |

| PendantWidgetShow | |

| PendantWidgetHide | |

| PendantWidgetHidden | |

| RunPLC | |

| SaveConfig | |

| SetG92 | Sets the current work position to the selected value (for example, SetG92 X0) |

| SetHWDAC | |

| SetHWOutputBit | |

| SetHWPWM | |

| SetPendant | |

| SetRotationAngle | |

| SetCNCVariable | |

| SetJog | |

| SetScale | |

| SetGVariable | |

| SinglePlay | |

| ShutDown | |

| GetJobName | Get the full job name and file path |

| GetSVariable8020 | Get the full job name and file path (same as GetJobName) |

| GetSVariable8109 | Get current job (file) size, in MB |

| GetSVariable8108 | Get the current job (file) folder path (same as GetJobName but without the actual file name) |

| GetSVariable8107 | Get the current job name without the folder path (name only) |

Server API, Jog control

Command “SetJog” is used for Jog control through Sever API. Command syntax is “SetJog Parameter”. Parameters listed in table below:

| Parameter | Description |

|---|---|

| x+ | start jog X+ direction |

| x- | start jog X- direction |

| y+ | start jog Y+ direction |

| y- | start jog Y- direction |

| z+ | start jog Z+ direction |

| z- | start jog Z- direction |

| a+ | start jog A+ direction |

| a- | start jog A- direction |

| b+ | start jog B+ direction |

| b- | start jog B- direction |

| c+ | start jog C+ direction |

| c- | start jog C- direction |

| x+y+ | start jog in 2 axes X+,Y+ directions |

| x-y- | start jog in 2 axes X-,Y- directions |

| x+y- | start jog in 2 axes X+,Y- directions |

| x-y+ | start jog in 2 axes X-,Y+ directions |

| xstop | stop jog in X axis |

| ystop | stop jog in Y axis |

| zstop | stop jog in Z axis |

| astop | stop jog in A axis |

| bstop | stop jog in B axis |

| cstop | stop jog in C axis |

| xystop | stop jog in X, Y axes |

Server API, Pendant control emulation

Server API has a command to simplify Pendant control emulation. This command can be used for writing third-party Pendant control device drivers.

SetPendant

Command: SetPendant

Format: SetPendant Parameter1;Parameter2

Parameter1- Emulated Hand wheel position. It's supposed the handwheel has resolution of “100”, such that the position range can be (0…99)Parameter2- 16-bit value, high byte is Step selector, low byte is Axis selector.- Step selector values can be set through the following format:

- 0 → “x0.001” (1 wheel step = 0.001 unit)

- 1 → “x0.01” (1 wheel step = 0.01 unit)

- 2 → “x0.1” (1 wheel step = 0.1 unit)

- 3 → “x1” (1 wheel step = 1 unit)

- Axis selector values:

- 0 → “OFF”

- 1 → “X”

- 2 → “Y”

- 3 → “Z”

- 4 → “A”

- 5 → “B”

- 6 → “C”

| Example | Description |

|---|---|

| SetPendant 50;0x0300 | Axis=OFF, Mul=1, Wheel=50 - initial position |

| SetPendant 50;0x0301 | Axis=X, Mul=1, Wheel=50 - Turn ON X axis |

| SetPendant 55;0x0301 | Axis=X, Mul=1, Wheel=55 - Rotate wheel +5 “clicks”, will move X +5*1.0=5.0 mm |

| SetPendant 55;0x0302 | Axis=Y, Mul=0.01, Wheel=55 - Switch to Y axis |

| SetPendant 65;0x0302 | Axis=Y, Mul=0.01, Wheel=65 - Rotate wheel +10 “clicks”, will move Y +10*0.01=+0.1 mm |

| SetPendant 65;0x0302 | Axis=Z, Mul=0.1, Wheel=65 - Switch to Z axis |

| SetPendant 50;0x0302 | Axis=Z, Mul=0.1, Wheel=50 - Rotate wheel -15 “clicks”, will move Z -15*0.1=-1.5 mm |

Hardware outputs (binary, DAC, PWM) manipulation thourgh Server API

There are 3 ways to manipulate myCNC control board Hardware outputs through Server API:

1) Direct manipulation through commands “SetHWBinaryOutput”, “SetHWDAC”, “SetHWPWM” 2) Manipulation through running PLC procedure with Hardware Outputs manipulation. 3) Manipulation though running short G/M-codes program

Direct Manipulation

Set HW Binary Output

Command: SetHWBinaryOutput

Syntax: SetHWBinaryOutput <Port number> <Port value>

Port Number is number binary port. Its range is 0 to 159. Set Port value to “1” to turn ON binary output (relay, open collector), “0” to turn OFF the binary output.

| Example | Description |

|---|---|

| SetHWBinaryOutput 0 1 | Turn ON binary output #0 |

| SetHWBinaryOutput 1 1 | Turn ON binary output #1 |

| SetHWBinaryOutput 23 1 | Turn ON binary output #23 |

| SetHWBinaryOutput 0 0 | Turn OFF binary output #0 |

| SetHWBinaryOutput 1 0 | Turn OFF binary output #1 |

| SetHWBinaryOutput 19 0 | Turn OFF binary output #19 |

Set HW PWM

Command: SetHWPWM

Syntax: SetHWPWM <PWM channel> <PWM value>

PWM channel is the number of the PWM pin. Software range is 0 to 3, however the number of PWM channels depends on the myCNC Ethernet controller model. Controllers ET1, ET3, ET5 each contain 3 PWM pins.

| Example | Description |

|---|---|

| SetHWPWM 0 2000 | Set value “2000” to PWM#0 (PWM1). Max PWM value is 4095 |

| SetHWPWM 0 0 | Set value “0” to PWM#0 (PWM1). Max PWM value is 4095 |

| SetHWPWM 2 3500 | Set value “3500” to PWM#2 (PWM3). Max PWM value is 4095 |

| SetHWPWM 1 4095 | Set value “4095” (Maximum) to PWM#1 (PWM2). Max PWM value is 4095 |

Set HW DAC

Command: SetHWDAC

Syntax: SetHWDAC <DAC channel> <DAC value>

DAC channel is number of the DAC pin. Software range is 0 to 1, however real number of DAC channels depends on myCNC Ethernet controller model. Controllers ET1 and ET3 each contain 1 DAC pins, while the ET5 controller contains 6 DAC pins.

| Example | Description |

|---|---|

| SetHWDAC 0 1000 | Assign value “1000” to DAC#0 (DAC1). Max DAC value is 4095 |

| SetHWDAC 0 0 | Assign value “0” to DAC#0 (DC1). Max DAC value is 4095 |

| SetHWDAC 1 4095 | Assign value “4095” (Maximum) to DAC#1 (DAC2) |

Manipulation through PLC procedure

Server API command “RunPLC” loads and runs PLC procedure on the controller end with a given parameter. We can run a PLC procedure that manipulates Hardware outputs to get a similar result. Normally, every profile configuration contains PLC procedures for Hardware outputs manipulation:

M62

PLC procedure: M62

Syntax: M62 <Parameter>

M62 allows the user to turn ON a binary output pin with a given number (Parameter=Port number)

| Example | Description |

|---|---|

| M62 1 | Turn ON binary output #1 |

| M62 0 | Turn ON binary output #0 |

| M62 15 | Turn ON binary output #15 |

M63

PLC Procedure: M63

Syntax: M63 <Parameter>

M63 allows the user to turn OFF a binary output pin with a given number (Parameter=Port number)

| Example | Description |

|---|---|

| M63 1 | Turn OFF binary output #1 |

| M63 0 | Turn OFF binary output #0 |

| M63 15 | Turn OFF binary output #15 |

DAC

Syntax: DAC <Parameter>

The low 12 bits (11…0) contain the value of DAC to be written, high bits (14..12) contain the DAC channel.

| Example | Description |

|---|---|

| DAC 0 | Set value “0” to DAC#0 (DAC1). Max DAC value is 4095 |

| DAC 0x0600 | Set value “0x600” (1536) to DAC#0 (DAC1). Max DAC value is 4095 |

| DAC 0x1400 | Set value “0x400” (1024) to DAC#1 (DAC2). Max DAC value is 4095 |

| DAC 0x1000 | Set value “0” to DAC#1 (DAC2). Max DAC value is 4095 |

PWM

Syntax: PWM <Parameter>

The low 12 bits (11…0) contain the value of PWM to be written, high bits (14..12) contain the PWM channel number.

| Example | Description |

|---|---|

| PWM 0 | Set value “0” to PWM#0 (PWM1). Max DAC value is 4095 |

| PWM 0x0600 | Set value “0x600” (1536) to PWM#0 (PWM1). Max PWM value is 4095 |

| PWM 0x1400 | Set value “0x400” (1024) to PWM#1 (PWM2). Max PWM value is 4095 |

| PWM 0x2000 | Set value “0” to PWM#2 (PWM3). Max PWM value is 4095 |

Examples of running these PLC procedures through the Server API are shown table below:

| Binary input manipulation | |

|---|---|

| Example | Description |

| RunPLC M62 1 | Turn ON output#1 |

| RunPLC M62 0 | Turn ON output#0 |

| RunPLC M63 3 | Turn OFF output#3 |

| RunPLC M63 5 | Turn OFF output#5 |

| PWM control | |

|---|---|

| Example | Description |

| RunPLC PWM 0x1350 | Write to PWM#1 (PWM2) a value of 0x350 |

| RunPLC PWM 0x250 | Write to PWM#0 (PWM1) value 0x250 |

| RunPLC PWM 0x2800 | Write to PWM#2 (PWM3) value 0x800 |

| RunPLC PWM 0x0 | Write to PWM#0 (PWM1) value 0 |

| RunPLC PWM 0x1000 | Write to PWM#1 (PWM2) value 0 |

| RunPLC PWM 0x2000 | Write to PWM#2 (PWM3) value 0 |

| SetHWDAC | |

|---|---|

| Example | Description |

| RunPLC DAC 0x1570 | Write to DAC#1 (DAC2) value 0x570 |

| RunPLC DAC 0x800 | Write to DAC#0 (DAC1) value 0x800 |

| RunPLC DAC 0x0 | Write to DAC#0 (DAC1) value 0 |

| RunPLC DAC 0x1000 | Write to DAC#1 (DAC2) value 0 |

Manipulation through running G-codes

Server API command “SinglePlay” will run a G-code line (or a number of G-code lines separated by the “;” symbol). It's possible to control binary outputs by running M-functions “M62” and “M63” (similar to the method described above). P-parameter sets the binary output number to control.

M-code: M62

Syntax: M62 P<number>

This will turn ON the binary output pin with the given number.

| Example | Description |

|---|---|

| M62 P1 | Turn ON binary output #1 |

| M62 P0 | Turn ON binary output #0 |

| M62 P15 | Turn ON binary output #15 |

Syntax: M63 P<number>

This will turn OFF the binary output pin with the given number.

| Example | Description |

|---|---|

| M63 P1 | Turn OFF binary output #1 |

| M63 P0 | Turn OFF binary output #0 |

| M63 P15 | Turn OFF binary output #15 |

Any custom PLC function can be written and assigned to M-code, then loaded through the CNC Server API.

Demo Videos

The following videos show examples of using the server API to control a myCNC system (older versions of the software are used, however the principle is the same):

ProgramFileOpen and SetScale:

Hardware Binary Outputs:

Set Scale and Rotation Angle: